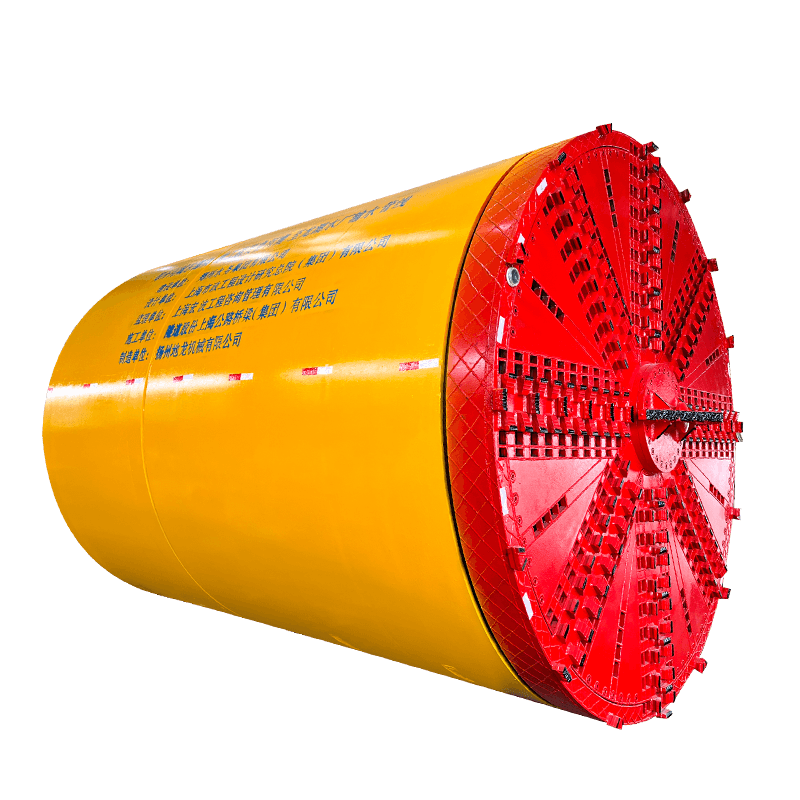

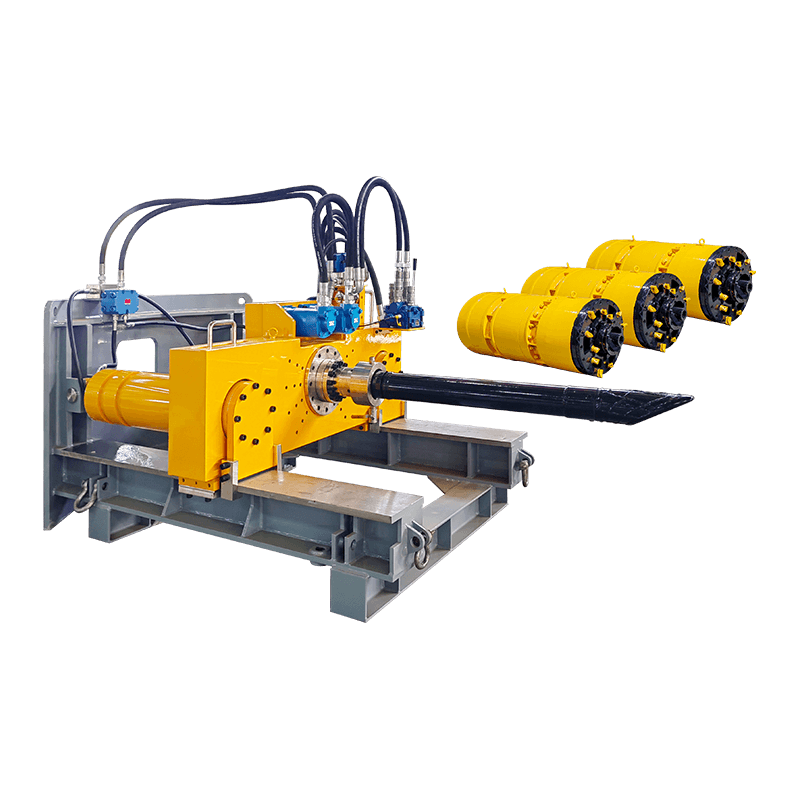

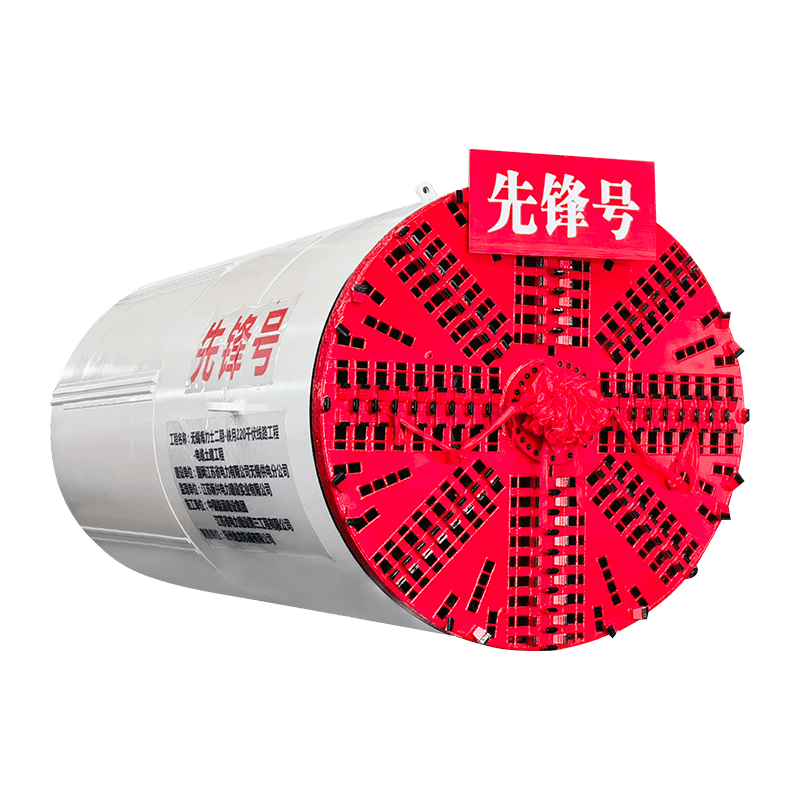

The Earth Pressure Balance (EPB) Shield Machine is a powerhouse when it comes to underground tunneling, particularly in challenging and unpredictable soil conditions. One of its standout features is its remarkable ability to perform efficiently across a variety of ground types, from cohesive clays to loose sands, and even mixed ground with fluctuating properties. This versatility is what makes the EPB Shield Machine indispensable for modern tunneling projects, especially in urban or complex subterranean environments.

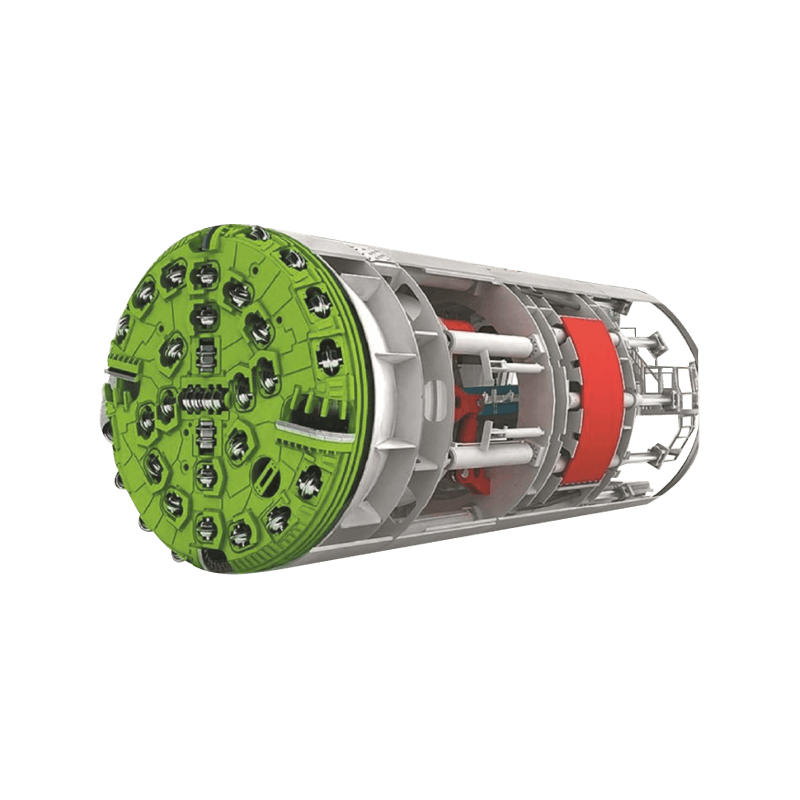

When tunneling through clay, the EPB Shield Machine excels due to its robust design, which includes a highly adaptable cutter head and a muck improvement system. Clays, particularly those with high moisture content or cohesive properties, can pose a serious challenge for traditional excavation methods. The EPB's system keeps the excavated material under control, preventing it from blocking the cutter head and maintaining a consistent, smooth operation. This is achieved through a combination of the machine's balance of pressure and the way it keeps the excavation face sealed. The machine's ability to maintain pressure at the tunnel face prevents the clay from collapsing, reducing the risk of tunnel instability. Its ability to transition to semi-open or closed mode is particularly beneficial in such conditions, allowing for adjustments as ground pressure increases or water ingress becomes a concern.

In sandy ground, where conditions are often looser and more prone to shifting, the EPB Shield Machine continues to shine. Sands are generally more forgiving in terms of excavation but come with their own set of risks, such as tunnel face collapse or loss of ground support. The key here is the machine's ability to control the balance of earth and pressure using the shield's powerful sealing system. By applying earth pressure behind the cutter head, the EPB helps stabilize the tunnel face even when faced with loose or shifting sand. This capability is critical in preventing the sudden collapse of the tunnel face or the unexpected release of soil into the machine’s chamber. Additionally, the real-time monitoring provided by the PLC system allows operators to fine-tune the earth pressure balance, ensuring that excavation continues smoothly, even in loose or grainy soil.

When encountering mixed ground, which often includes varying layers of soft and hard soils, the EPB Shield Machine’s adaptability is key to its success. Mixed ground conditions can be particularly tricky, as they might involve sudden shifts from one soil type to another, creating inconsistent pressure conditions at the tunnel face. The EPB Shield Machine handles this variability by offering the option to switch between open, semi-open, and closed modes, adjusting to the varying pressures and composition of the ground. For example, in areas where the soil is particularly soft or highly water-saturated, switching to a closed mode provides added protection against water ingress and ground settlement. On the other hand, in more stable or compact layers, an open or semi-open mode might be used for more efficient excavation.

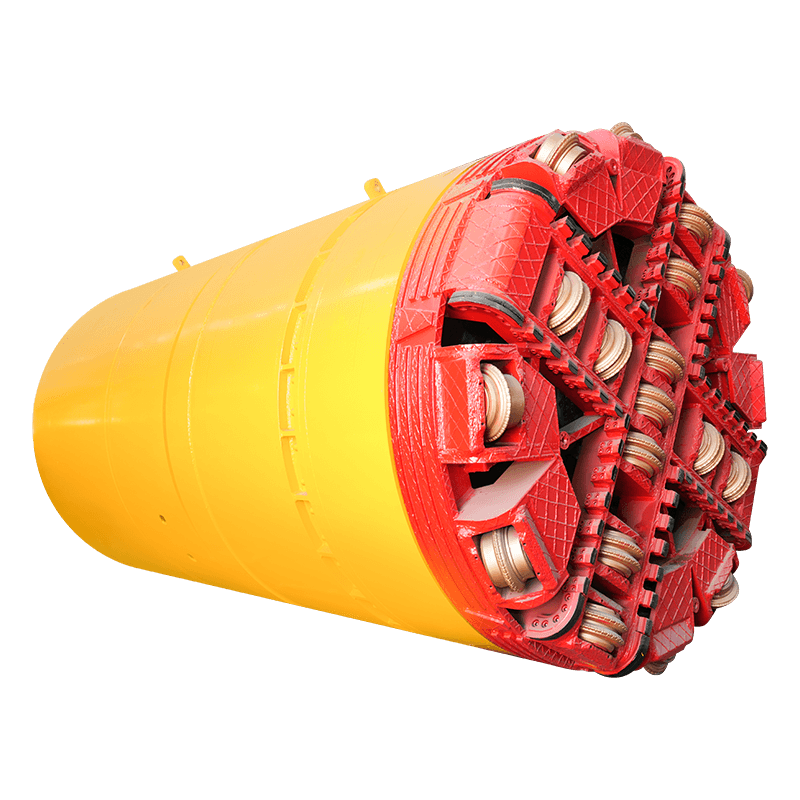

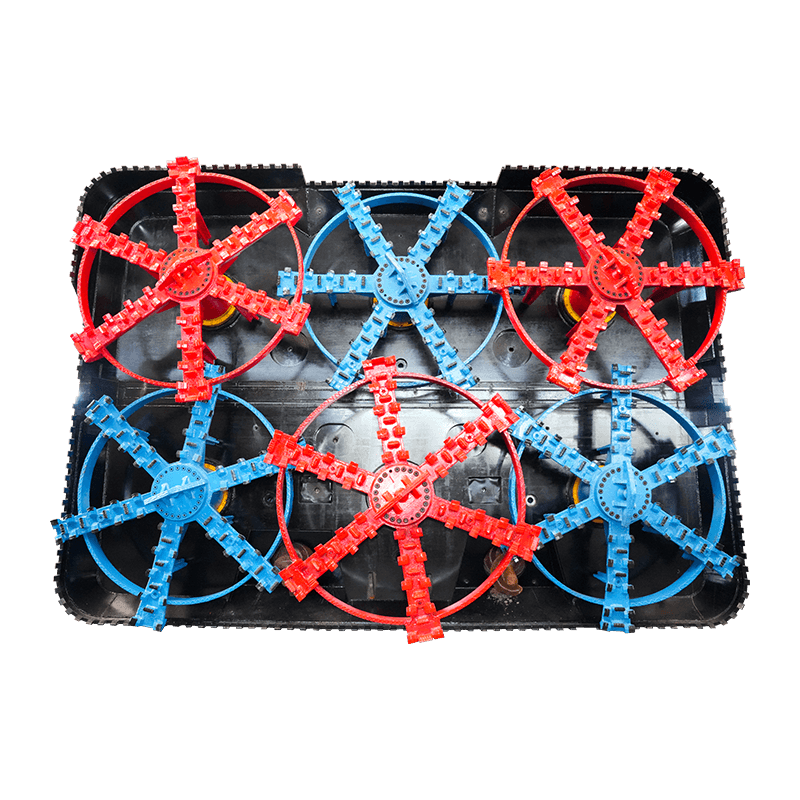

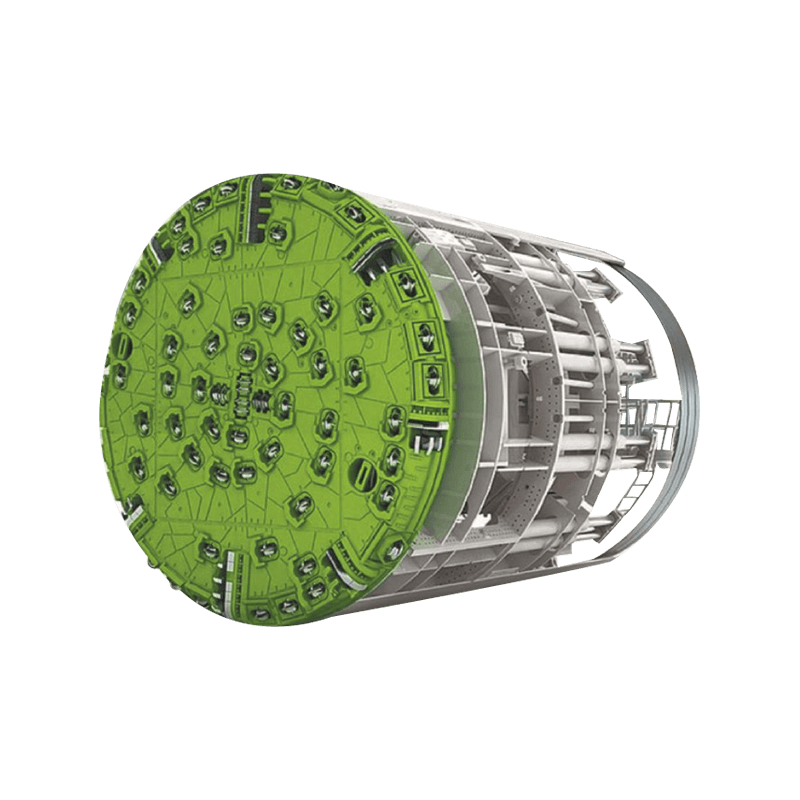

The machine’s cutter head is another factor that plays a significant role in mixed ground performance. Designed to tackle a range of materials, it is capable of cutting through both soft soils and harder layers without losing efficiency. Its advanced design, combined with the muck improvement system, ensures that no matter the material being excavated, it’s processed and removed quickly to prevent build-up that could affect machine performance. Whether it’s soft clay, grainy sand, or a combination of both, the cutter head works in harmony with the shield’s pressure control systems to maintain a steady, uninterrupted excavation process.

Additionally, the muck improvement system ensures that even when the ground conditions are inconsistent, the spoil is removed and processed in a way that maintains optimal operation. In mixed ground, where the soil characteristics can shift rapidly, this system helps manage and regulate the removal of material, ensuring that the cutter head isn’t blocked by overly sticky or excessively loose spoil.

What sets the EPB Shield Machine apart from other tunneling equipment is its ability to provide real-time data monitoring and adjustments via its integrated PLC system. This system continually assesses the condition of the excavation face and the surrounding soil, allowing operators to make quick decisions and adapt the machine’s settings to optimize performance. For instance, if there’s a sudden shift from a clay layer to loose sand, the system can alert the operators, who can then adjust the machine’s settings to account for the changing conditions. This kind of flexibility makes the EPB Shield Machine particularly well-suited to unpredictable mixed ground, where conditions can change dramatically with

English

English  русский

русский  عربى

عربى