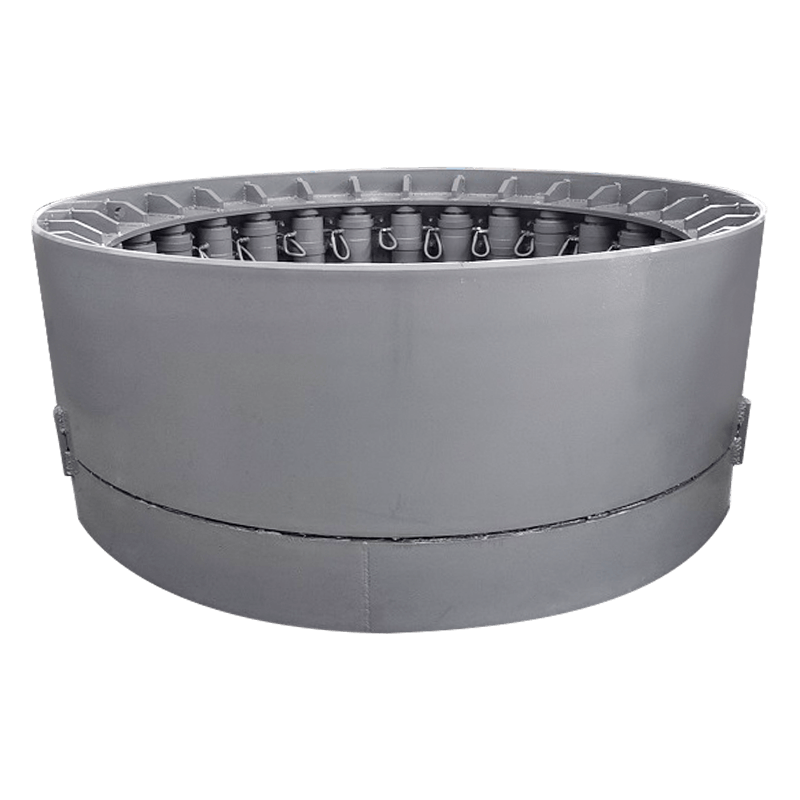

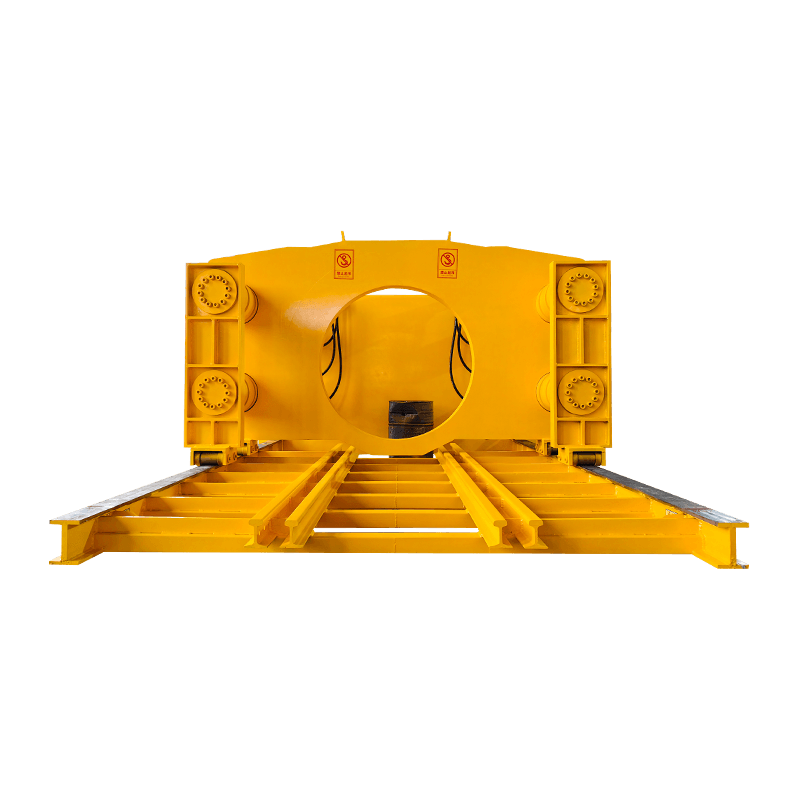

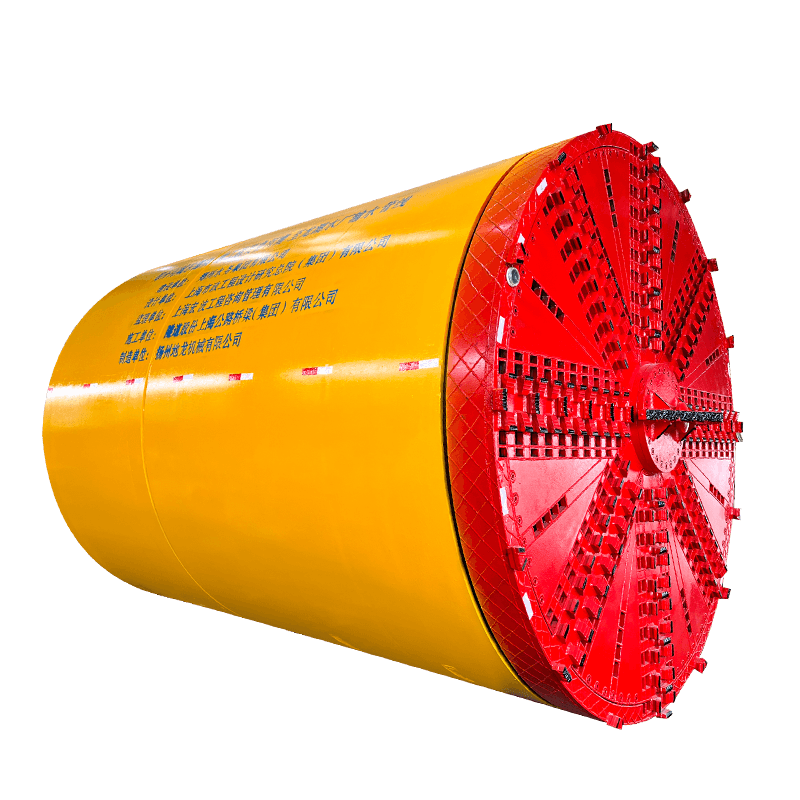

The Rock Pipe Jacking Machine is an advanced solution for installing pipelines in challenging ground conditions, particularly in rock, boulders, and mixed soil environments. One of its most impressive features is the internal cone crushing plant, a key component that enhances the machine’s ability to handle tough and variable geological conditions. But how exactly does this internal crushing system deal with very large boulders or mixed soil layers, and why is it such a crucial part of the machine’s design? Let’s delve into the mechanics and benefits of this innovative feature.

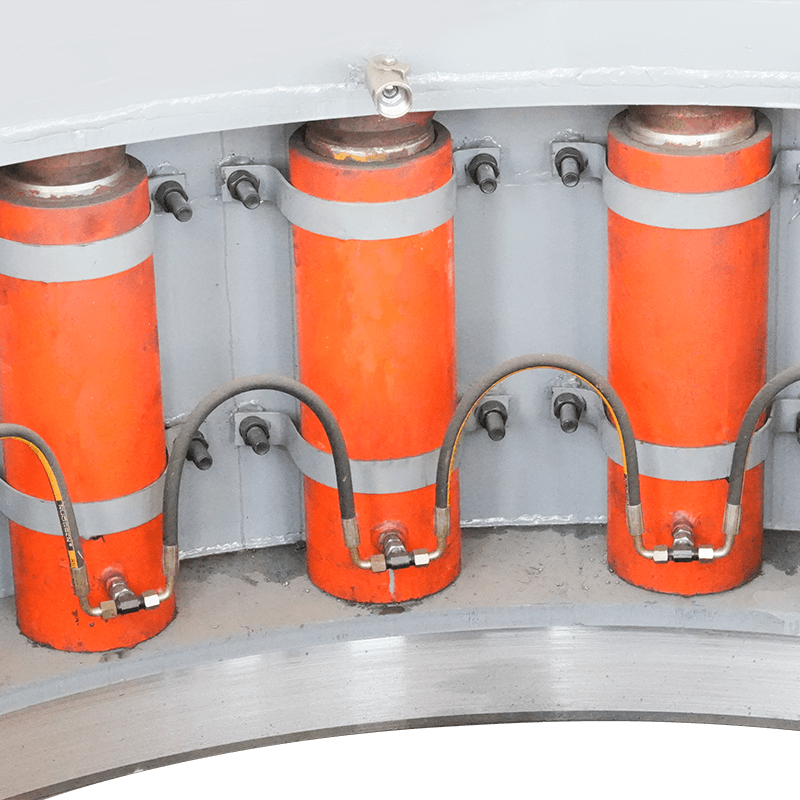

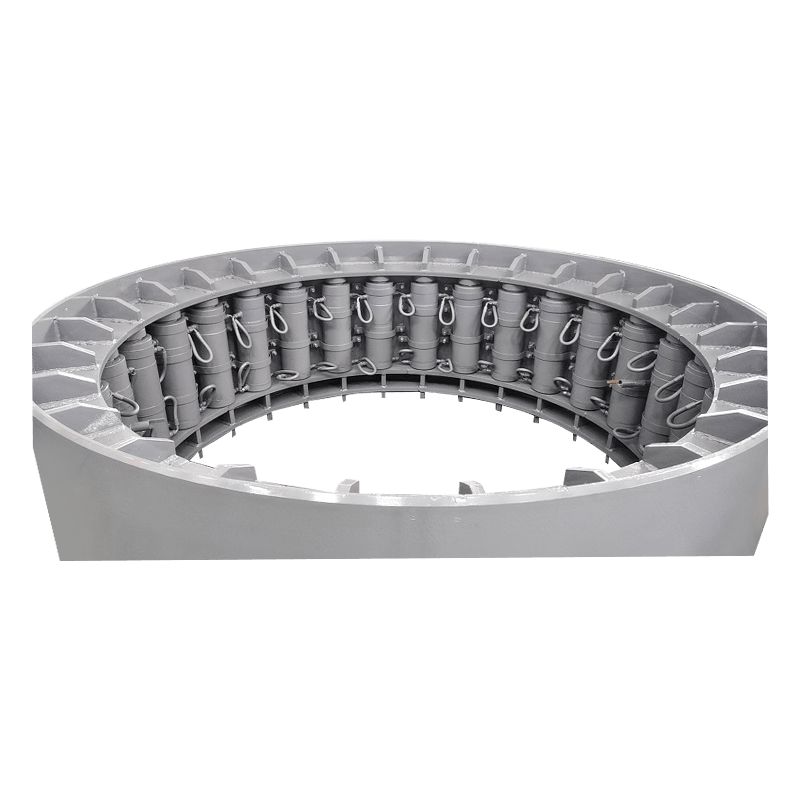

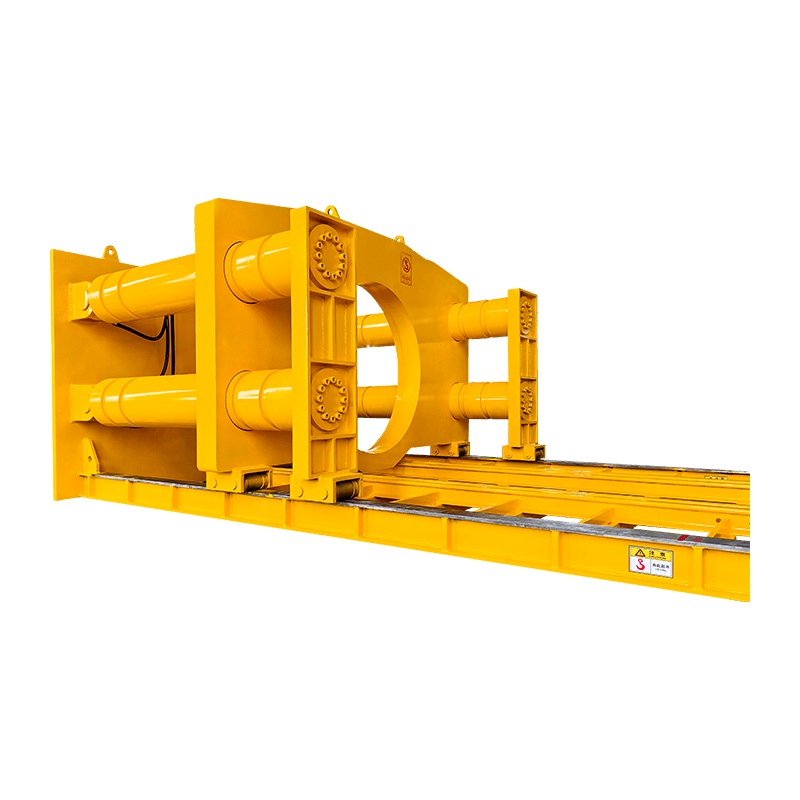

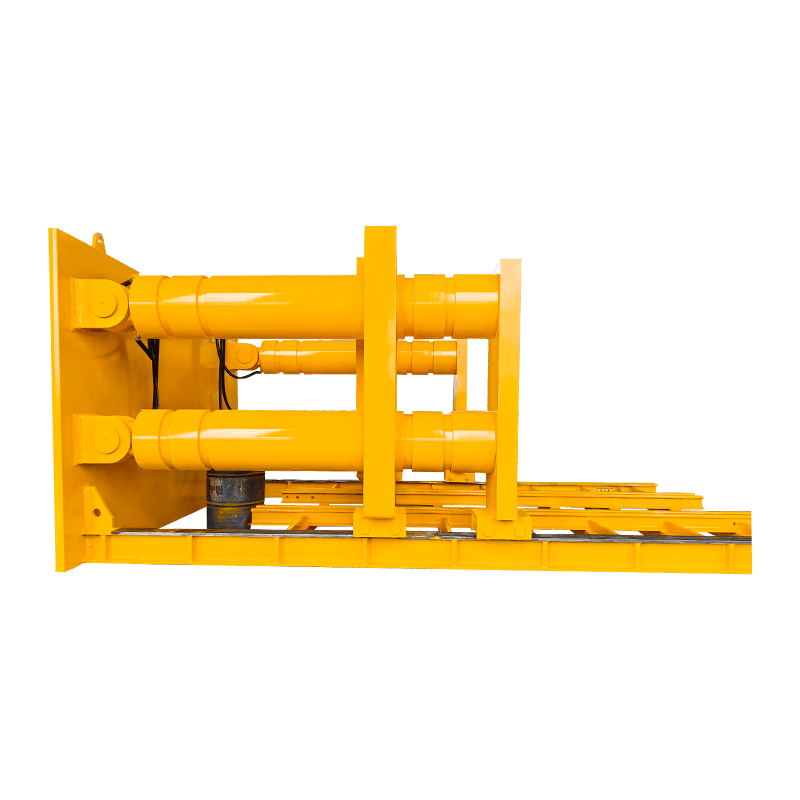

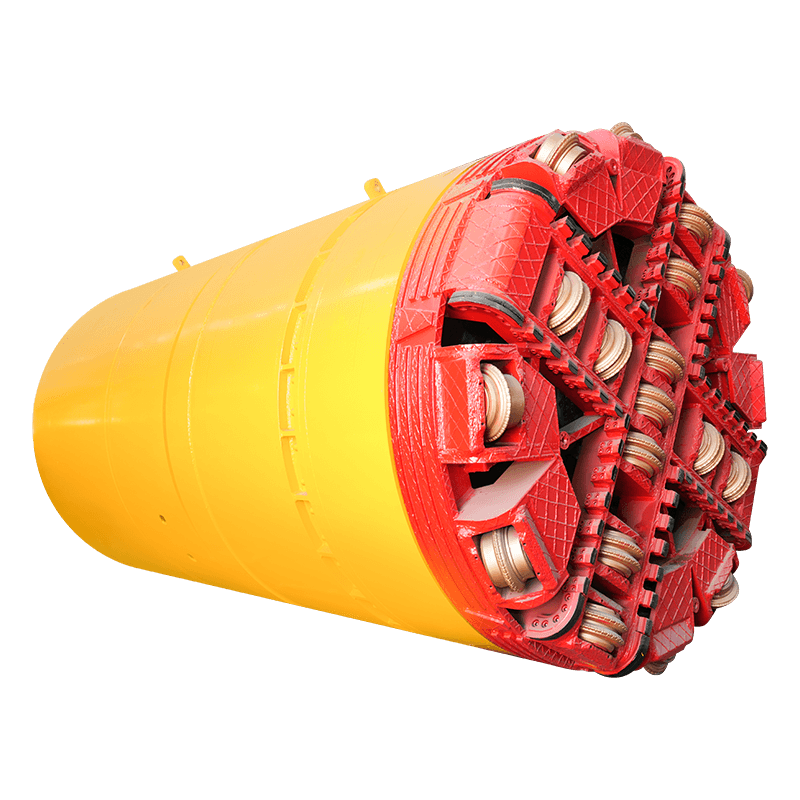

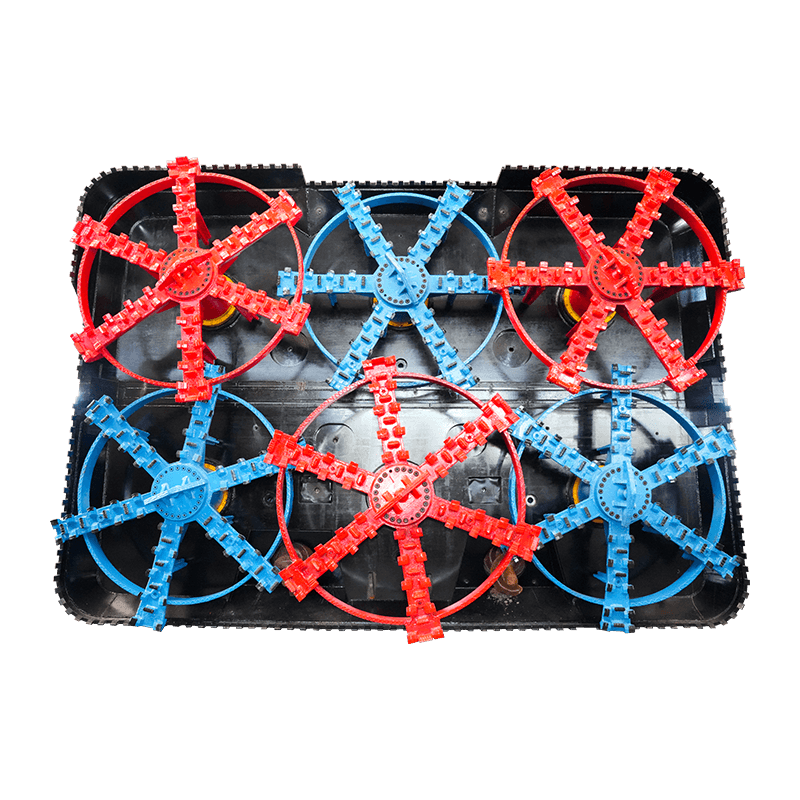

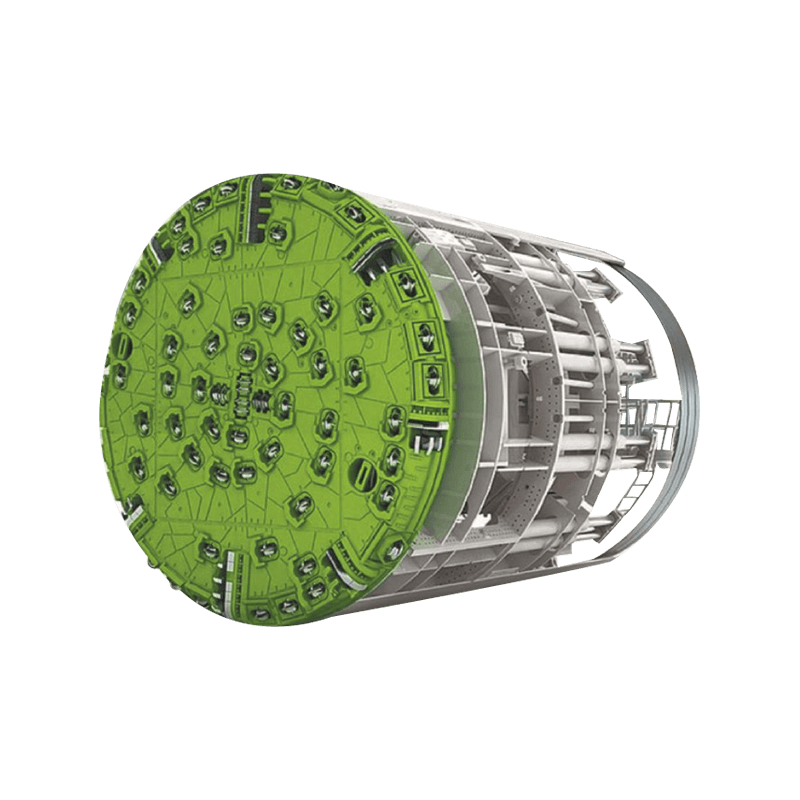

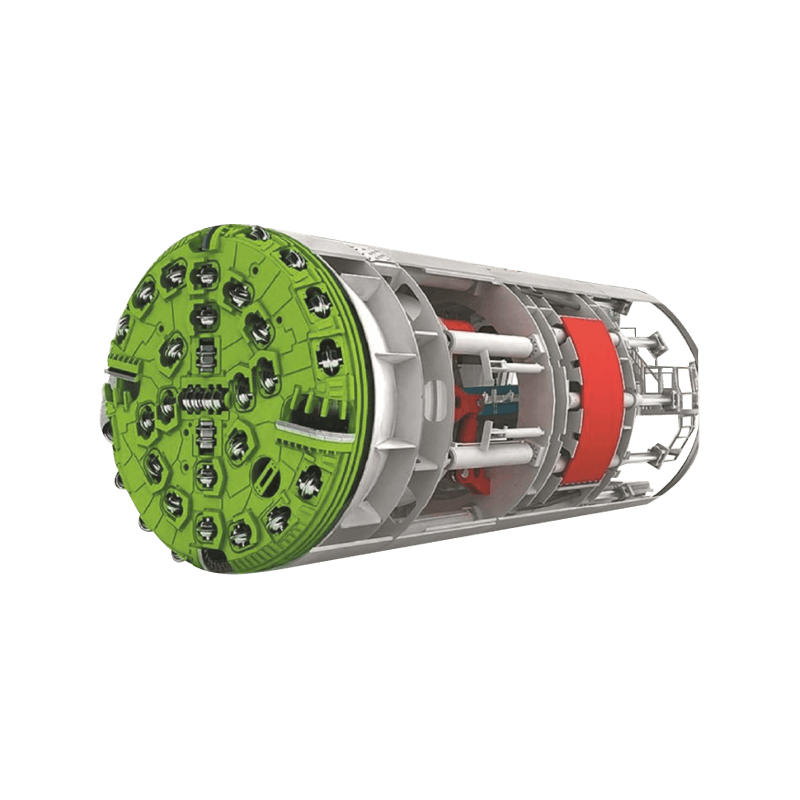

The internal cone crushing plant works by breaking down large rocks and boulders into smaller, more manageable fragments during the jacking process. This secondary crushing mechanism plays a pivotal role in reducing the strain on the machine’s primary cutter bits, allowing the Rock Pipe Jacking Machine to maintain consistent progress even when faced with hard rock or mixed soil layers. When dealing with tough materials like large boulders or dense bedrock, traditional methods would require frequent stoppages for excavation and manual processing of the debris. However, the internal cone crusher eliminates this need by crushing the materials in situ, keeping the machine moving forward efficiently without requiring significant downtime for manual handling.

The crushing plant is designed to handle varying rock hardness levels, ranging from relatively soft formations to those with a hardness of up to 200 MPa. As the cutter bits advance through the soil, they encounter a mix of soft soil, gravel, boulders, and bedrock. When the bits encounter larger obstacles—such as a massive boulder or particularly stubborn bedrock—the internal cone crushing plant activates to crush these larger particles into smaller, uniform sizes. The ability to crush large boulders in this way ensures that the machine’s progress is uninterrupted and that the pipe being jacked is not hindered by oversized debris or rocks that could otherwise block the passage. By breaking down the material into smaller fragments, the internal crusher also reduces the risk of damaging the machine's main components, such as the cutter head and thrust systems, which would be at risk of overloading from too large or dense material.

One of the key benefits of this internal cone crushing system is its versatility. Whether the machine is dealing with giant boulders, mixed soil conditions, or even hard bedrock, the crusher ensures that the jacking process can proceed smoothly. The system is engineered to adapt to different types of soil and rock, offering flexibility that is critical for long-distance pipe installations through varied terrain. This adaptability is essential in real-world construction environments where the geological conditions often change unexpectedly, requiring machinery that can cope with multiple types of soil and rock without compromising efficiency.

The internal cone crusher doesn’t just facilitate the jacking process by reducing rock size—it also contributes to the overall performance of the machine by increasing operational efficiency. When large rocks are broken down on-site, the material is easier to transport and manage. This minimizes the need for additional equipment or labor to handle debris, resulting in lower operational costs and quicker project completion times. Moreover, by breaking up large rocks and boulders before they reach the cutting head, the system helps to prevent blockages and mechanical failures that might otherwise result from trying to pass oversized material through the machine.

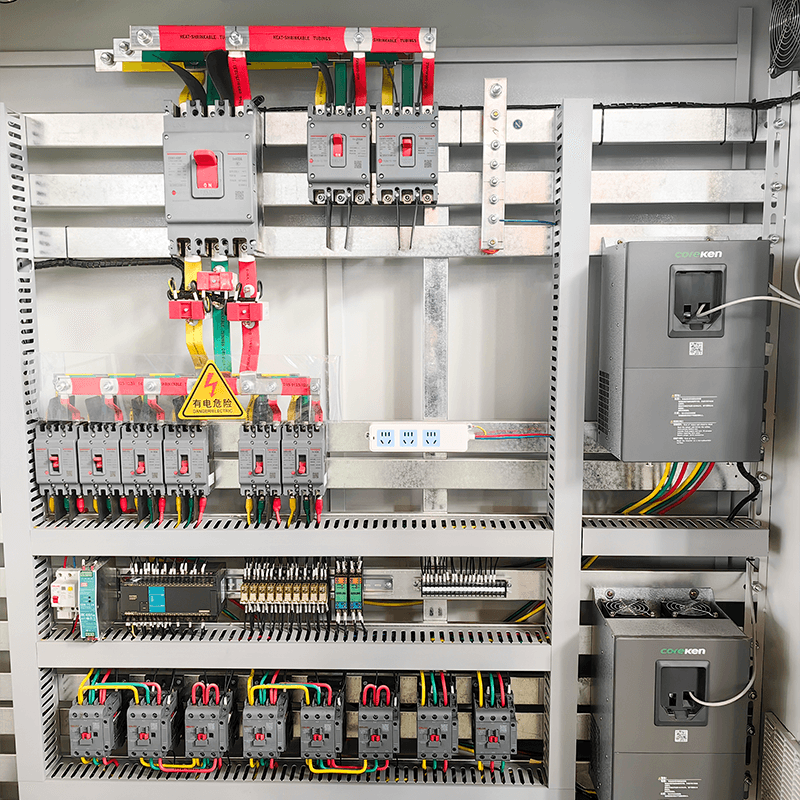

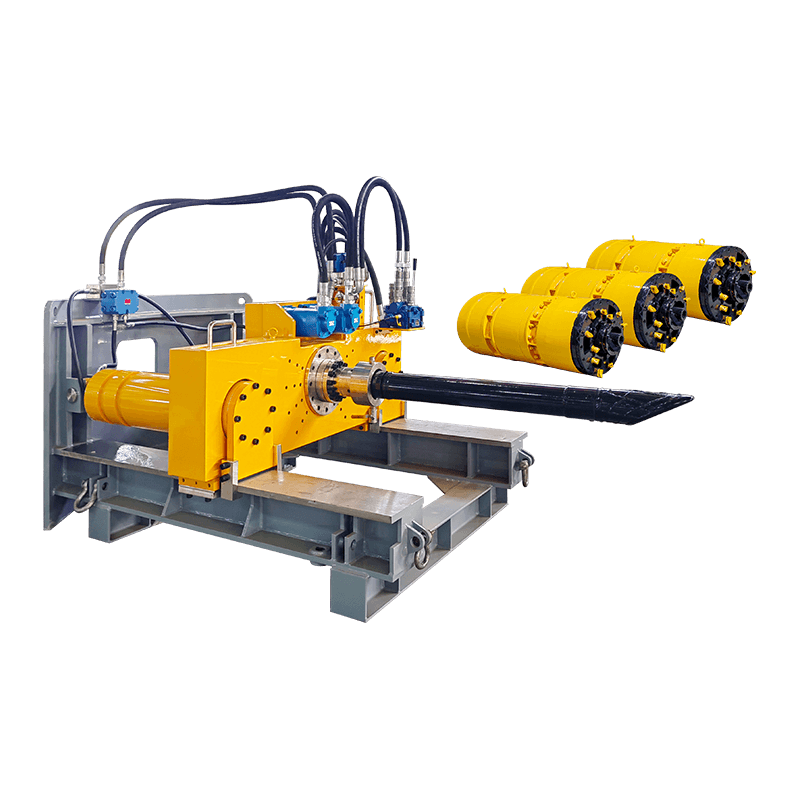

Additionally, this secondary crushing process is closely monitored through the ground computer control system. The system provides real-time data on the cutting and crushing progress, which allows the operator to adjust parameters such as speed and force based on the material encountered. If particularly hard or large boulders are detected, the operator can modify the machine's operational parameters to optimize crushing efficiency and ensure that the machine’s thrust capabilities are not overburdened. This not only enhances safety but also ensures that the operation remains smooth, even under the most difficult conditions.

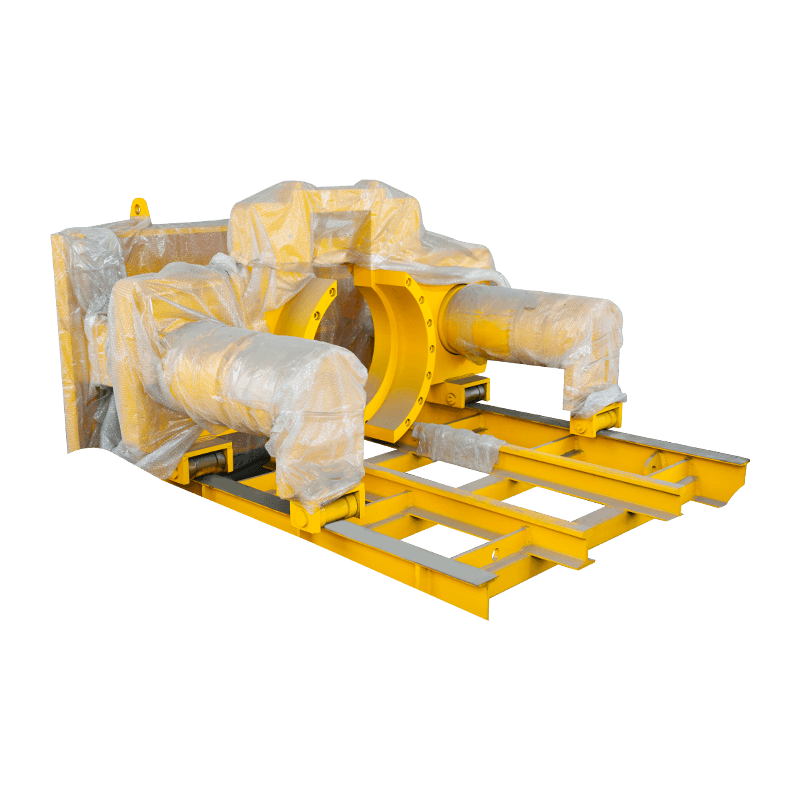

The combination of cutting-edge internal crushing technology and real-time monitoring makes the Rock Pipe Jacking Machine an invaluable tool for underground infrastructure projects, particularly those that require the installation of pipelines in areas with challenging terrain. Whether it's boulders, mixed soils, or bedrock, the internal cone crushing plant is designed to handle these obstacles with ease, ensuring that projects stay on track and are completed on time and within budget. This technology exemplifies how modern machinery can tackle the most demanding environmental challenges with efficiency, precision, and minimal disruption to the surrounding area.

English

English  русский

русский  عربى

عربى