During the use of Auger Boring Machine, timely detection and handling of possible faults or problems of the machine is crucial to ensure operating efficiency, extend equipment life and ensure construction safety. The following are some suggestions and methods to help operators detect and handle faults or problems of the Auger Boring Machine in a timely manner:

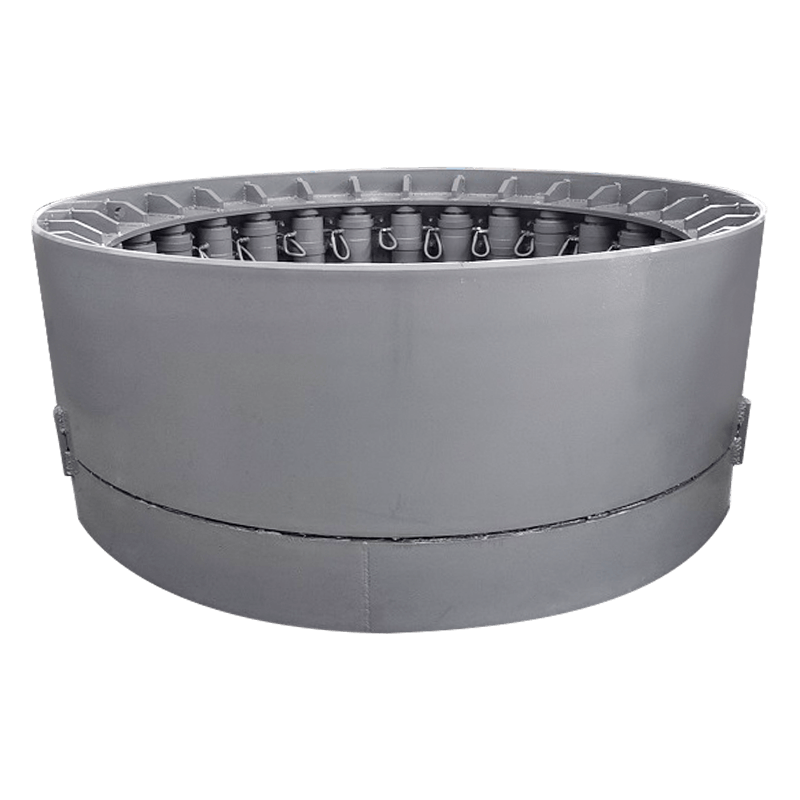

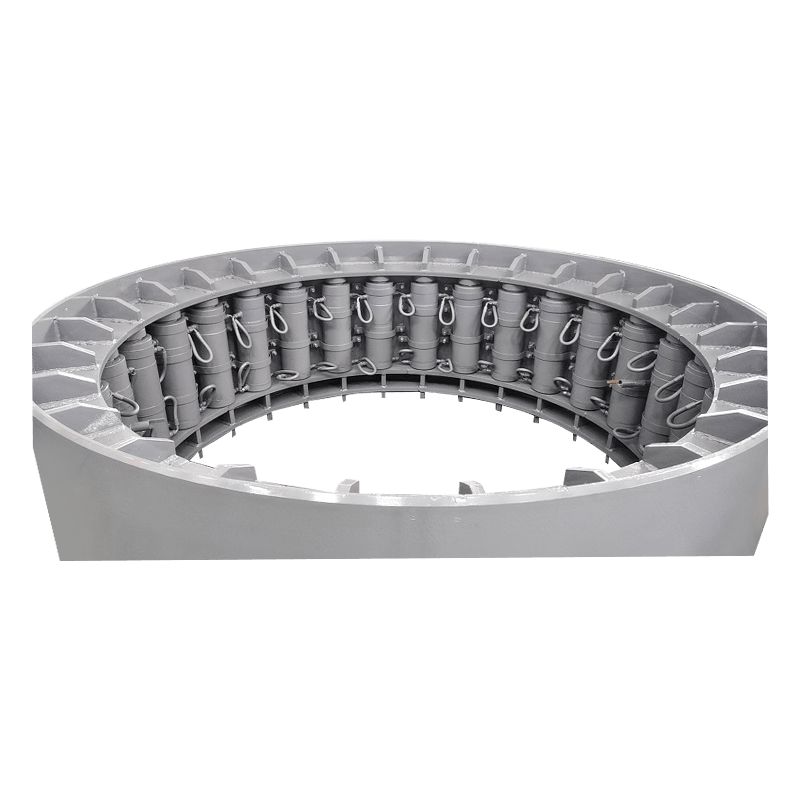

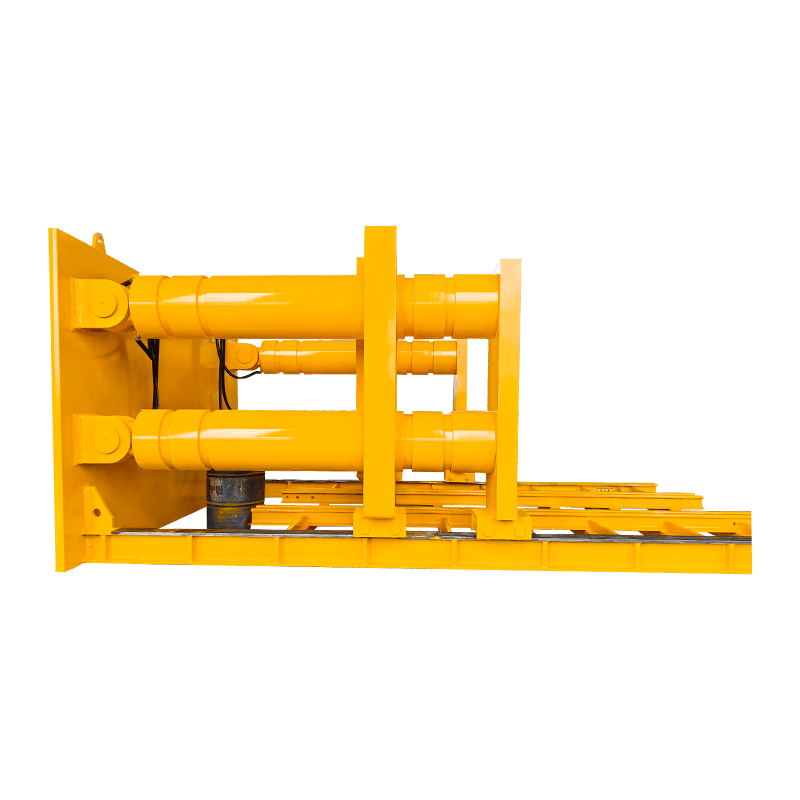

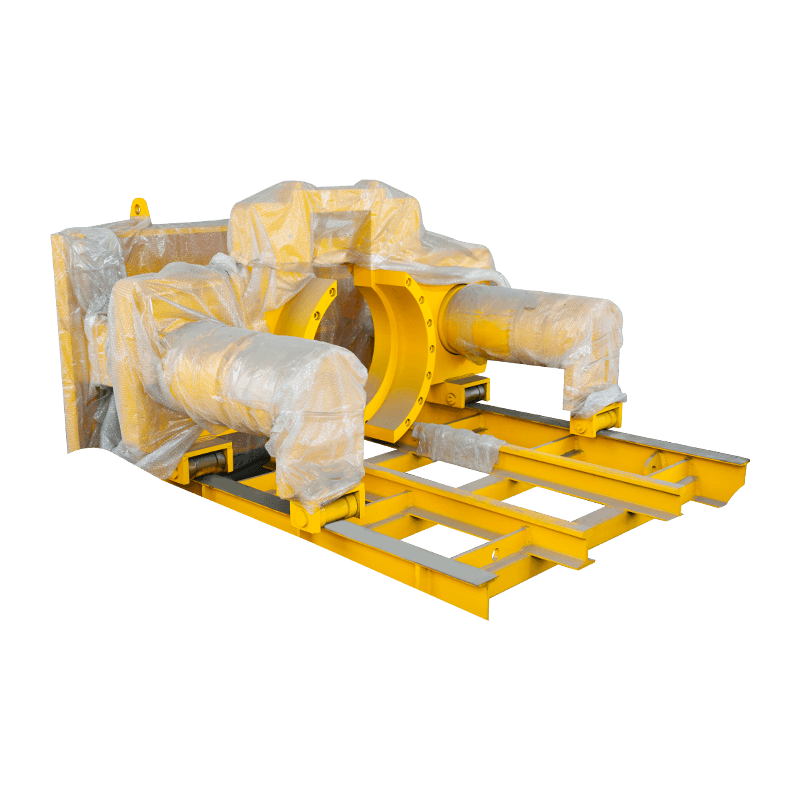

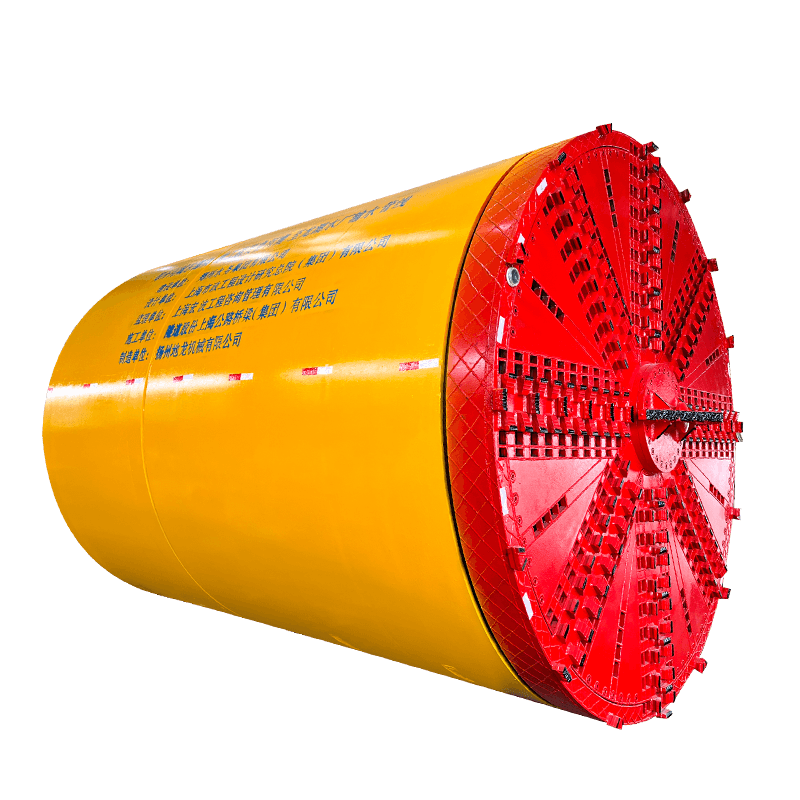

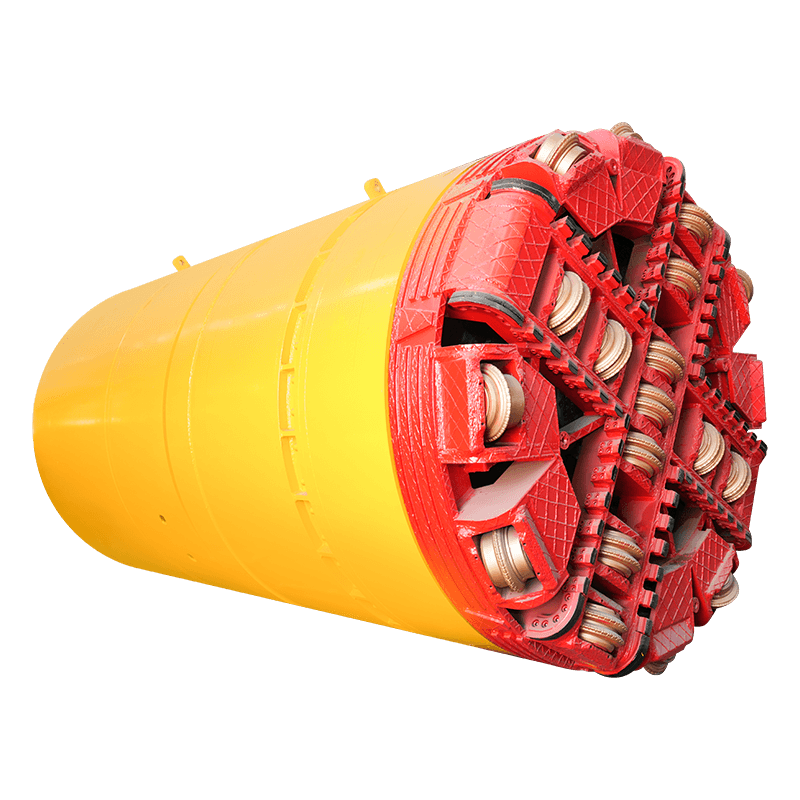

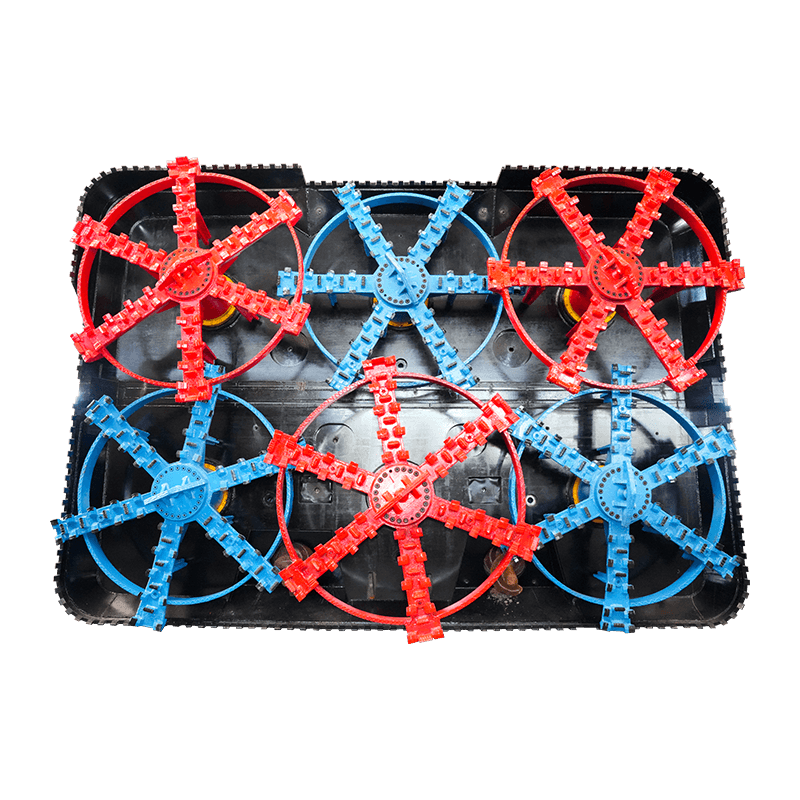

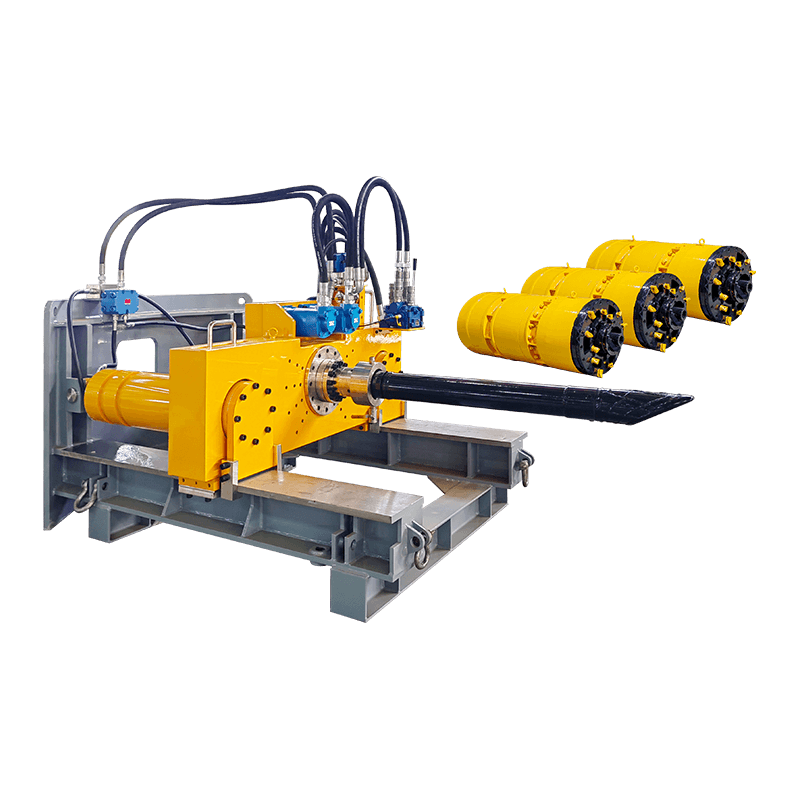

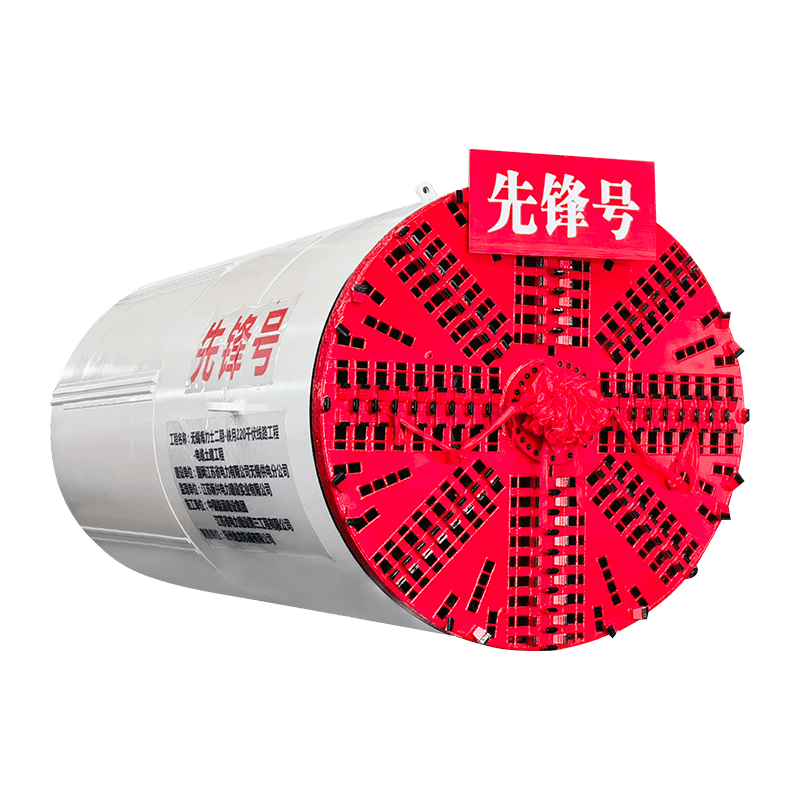

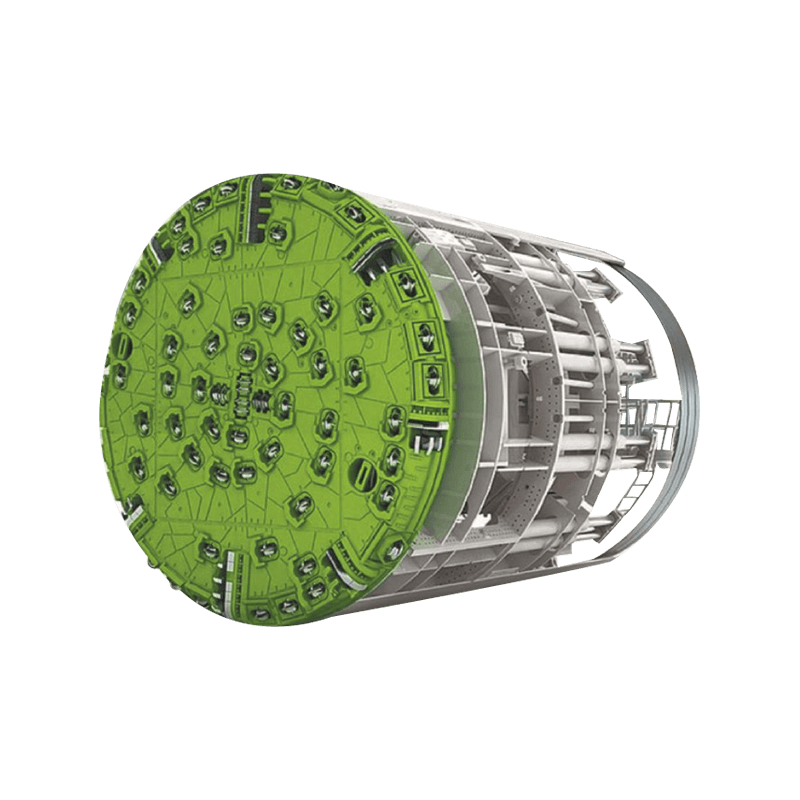

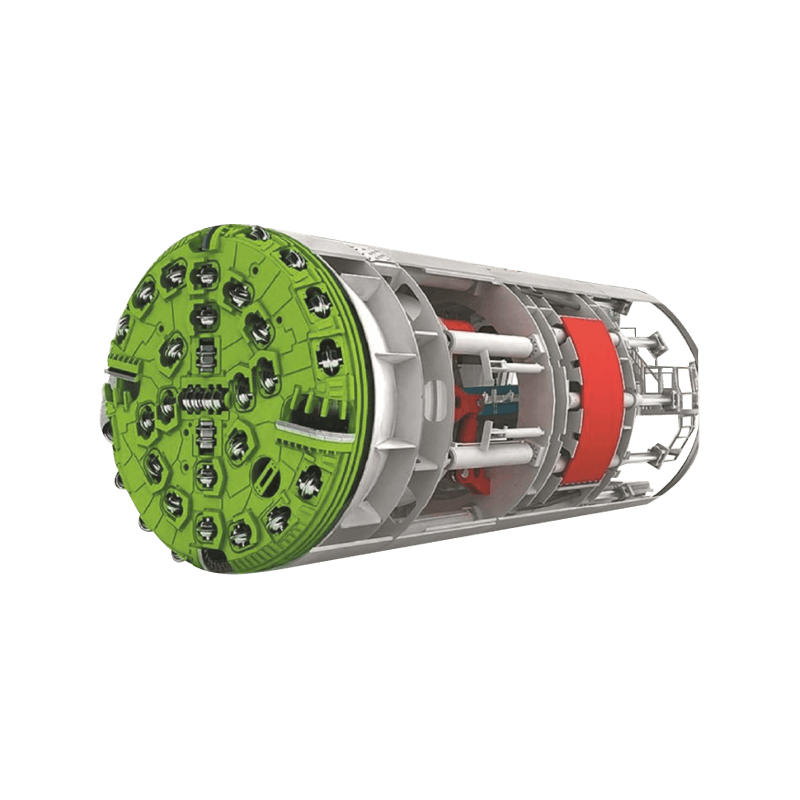

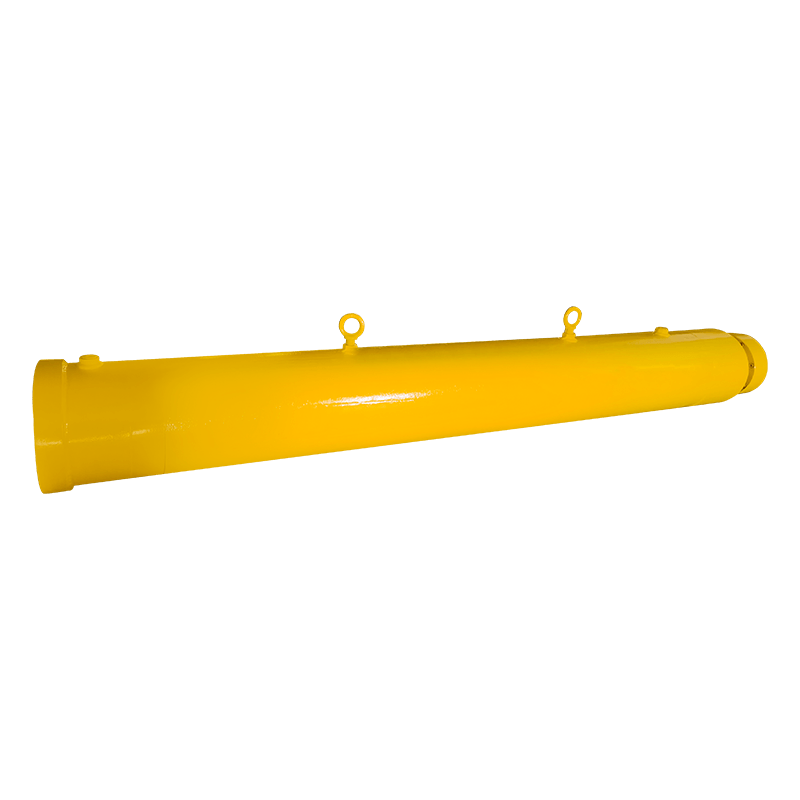

Regularly check the appearance of the machine, including whether the paint is peeling, whether the fasteners are loose, whether the wires and cables are damaged, etc. Pay special attention to checking the wear and damage of the drill rod, drill bit and connecting parts.

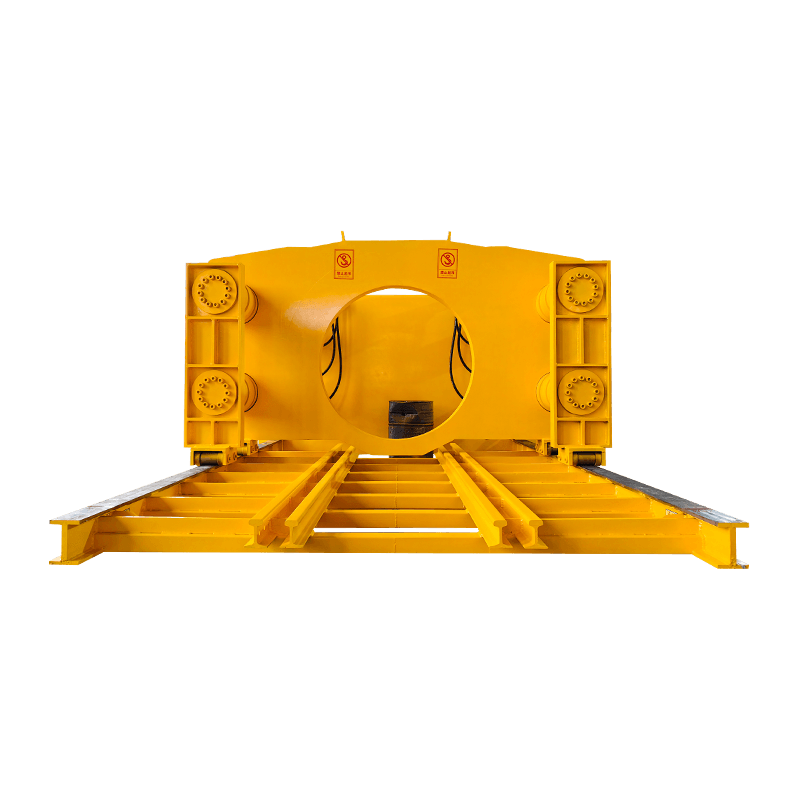

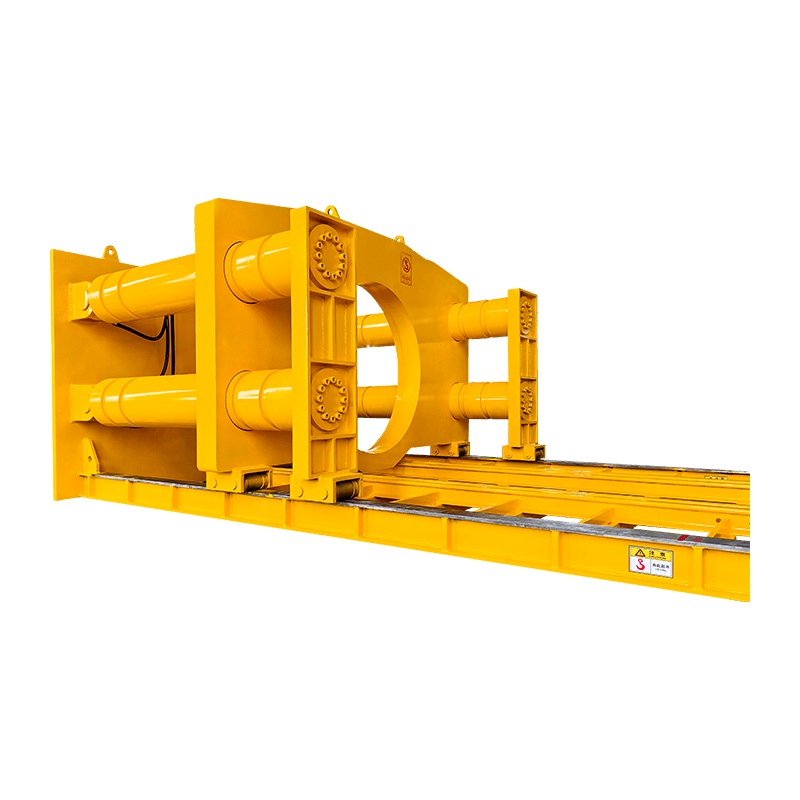

Before each use, perform simple functional tests, such as starting the motor, rotating the drill bit, etc., to ensure that all components are working properly. Check the pressure stability of the hydraulic system, as well as the oil level and oil quality of the oil tank.

Regularly lubricate the lubrication points of the machine to ensure the flexibility and wear resistance of the moving parts. Check the cleanliness and replacement cycle of the lubricating oil to avoid faults caused by poor lubrication.

During the operation of the machine, pay attention to listening for abnormal sounds, such as metal friction sounds, impact sounds, etc. Once an abnormal sound is found, the machine should be stopped for inspection immediately to avoid the expansion of the fault.

Observe the vibration of the machine. Abnormal vibration may mean problems such as bearing damage, loose connection or imbalance. Check the temperature of components such as motors and hydraulic pumps regularly to avoid failures caused by overheating.

Pay close attention to the readings of instruments such as pressure gauges and sensors to detect abnormal pressure or sensor failure in time. Adjust drilling parameters according to instrument readings to ensure that the machine operates in the best condition.

Every time a failure occurs, record the failure phenomenon, treatment method and treatment results in detail.

By analyzing the fault records, find out the rules and causes of the failure and formulate preventive measures.

Conduct regular training for operators to improve their fault identification and handling capabilities.

Ensure that operators are familiar with the structure, working principle and common fault handling methods of the machine.

Prepare sufficient spare parts, such as drill bits, bearings, seals, etc.

In the event of a failure, the damaged parts can be quickly replaced to restore the normal operation of the machine.

Through daily inspection and maintenance, monitoring during operation, and the implementation of fault handling and preventive measures, the failures or problems that may occur during the use of Auger Boring Machine can be discovered and handled in time. This will help improve operating efficiency, extend equipment life and ensure construction safety.

English

English  русский

русский  عربى

عربى