It is crucial to maintain the stability of the drill bit and the accuracy of the drilling during the drilling process of the Auger Boring Machine, which is directly related to the efficiency and quality of the drilling operation. The following is a detailed answer to this question:

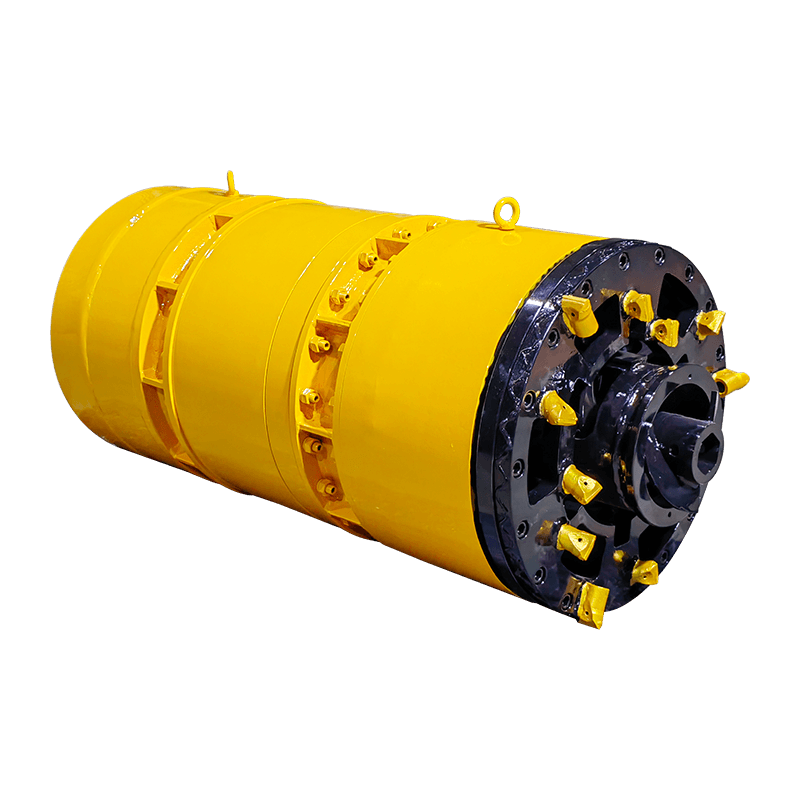

The shape and material selection of the drill bit have a direct impact on stability. High-quality drill bits are usually made of wear-resistant and high-strength materials to ensure that they are not easily deformed or damaged during the drilling process.

The cutting edge part of the drill bit is specially designed to disperse the cutting force more effectively, reduce vibration, and thus improve stability.

The connection method between the drill rod and the drill bit is also crucial. A firm connection can ensure that the drill bit will not fall off or loosen due to excessive force during the drilling process.

Usually, a threaded connection or a quick connection device is used between the drill rod and the drill bit to ensure the reliability and stability of the connection.

Reasonable adjustment of parameters such as drilling speed, rotation speed and feed pressure plays a key role in maintaining the stability of the drill bit.

Too fast drilling speed or excessive feed pressure may cause uneven force on the drill bit, resulting in vibration. Therefore, in actual operation, these parameters need to be adjusted according to geological conditions and drill bit characteristics.

Auger Boring Machine is usually equipped with a precise guidance system to ensure that the drill bit can move along the predetermined trajectory during the drilling process.

The guidance system usually includes components such as guide frames, guide wheels and guide plates, which work together to ensure the accurate positioning of the drill bit.

The degree of wear of the cutting edge directly affects the drilling accuracy. Therefore, it is necessary to regularly check the wear of the cutting edge and replace or grind it in time.

By adopting wear-resistant materials or coating technology, the service life of the cutting edge can be extended while maintaining high drilling accuracy.

During the drilling process, parameters such as the diameter, depth and position of the borehole need to be monitored in real time to ensure the drilling accuracy.

Once deviations or abnormalities are found, adjustments should be made immediately to ensure that the drilling operation can proceed smoothly.

During the drilling process, Auger Boring Machine maintains the stability of the drill bit and the accuracy of drilling by optimizing the drill bit design, strengthening the connection between the drill rod and the drill bit, reasonably adjusting the drilling parameters, adopting a precise guidance system, controlling the wear of the cutting edge, and real-time monitoring and adjustment. These measures work together to ensure efficient, accurate and reliable drilling operations.

English

English  русский

русский  عربى

عربى