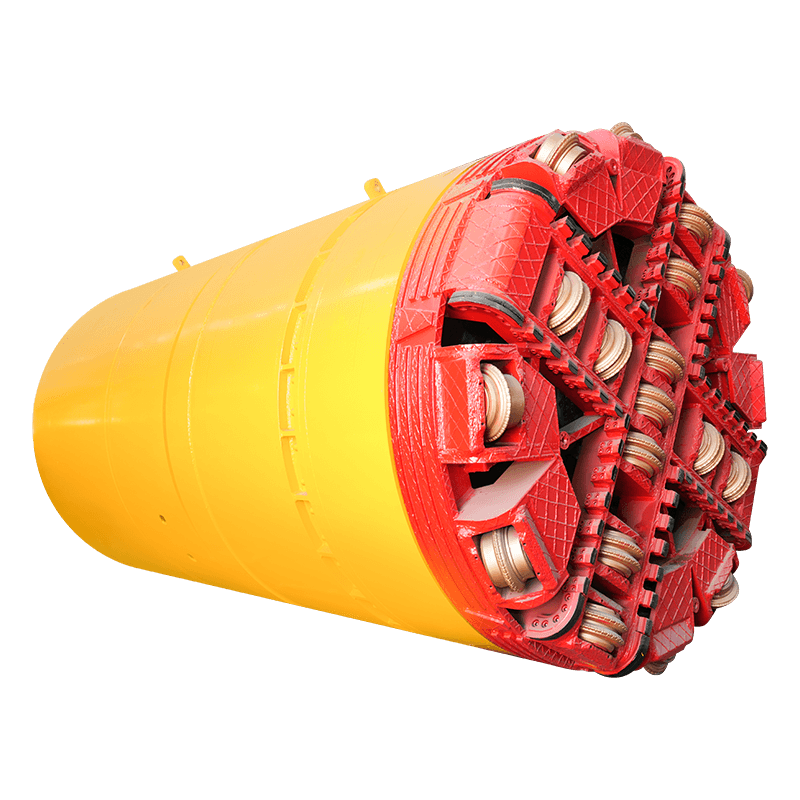

1. Efficient propulsion system

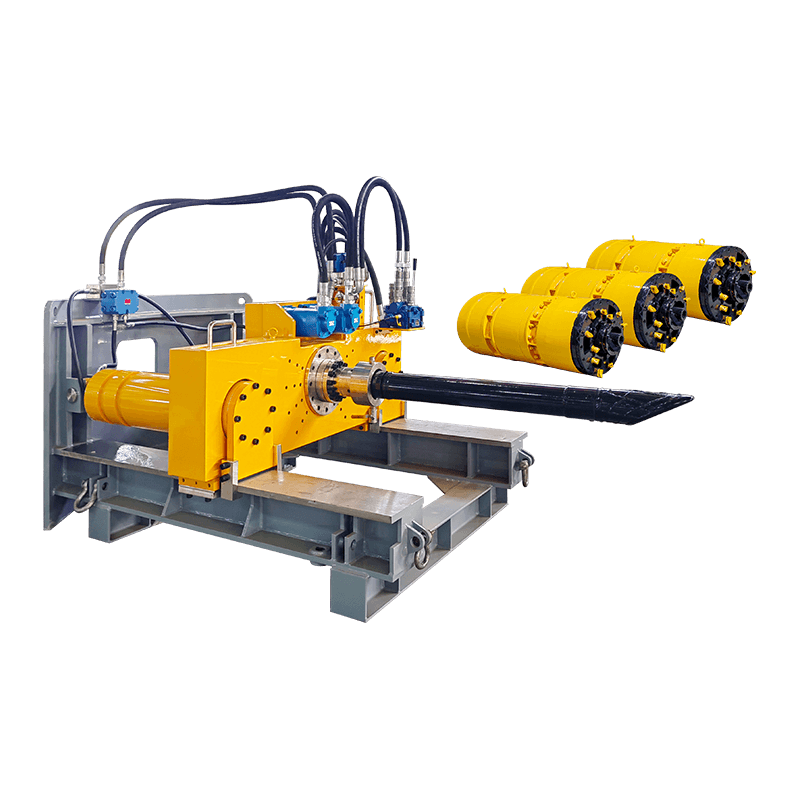

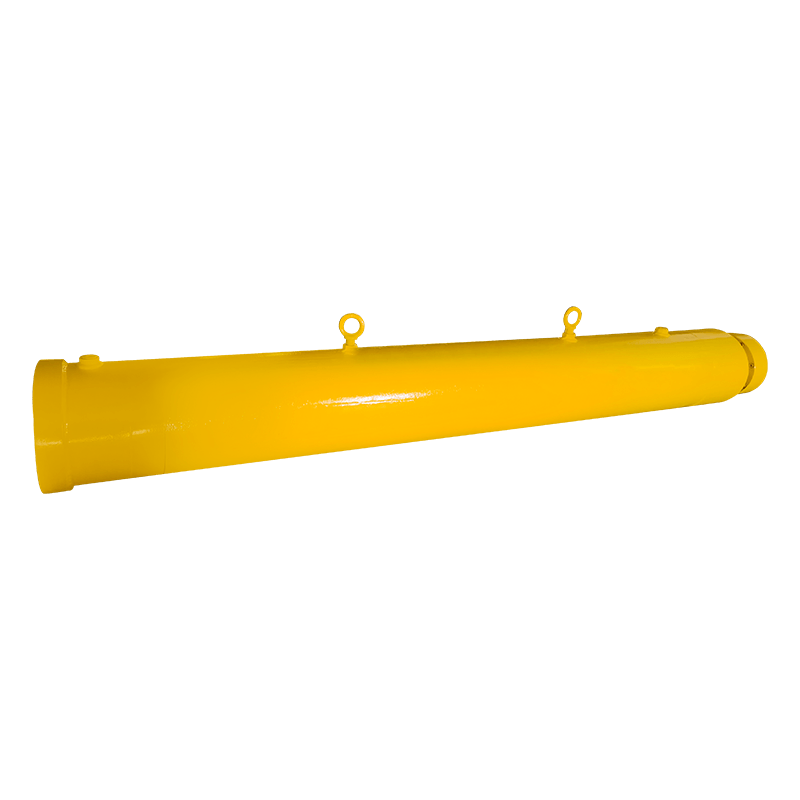

Modern pipe jacking machines are equipped with more powerful and efficient propulsion systems, which can provide continuous and stable propulsion in complex underground environments to ensure that the pipeline can be laid smoothly to the designated location. These propulsion systems use hydraulic, mechanical or electric propulsion methods, allowing the machine to continuously propel over a long pipe length.

Specific performance:

Hydraulic propulsion system: The hydraulic system can provide large thrust to meet the propulsion needs of different soil types, especially in harder or more sticky soils.

Electric propulsion system: With the advancement of electrification technology, electric propulsion systems can provide more efficient and energy-saving propulsion forces in some cases, while reducing the maintenance cost of equipment.

Application scenario: In the renovation of urban underground pipelines, water supply, drainage and power pipelines, the efficient propulsion system of modern pipe jacking machines can effectively shorten the construction period and improve the operation efficiency, especially in the laying of long-distance and large-diameter pipelines.

2. Accurate positioning and navigation technology

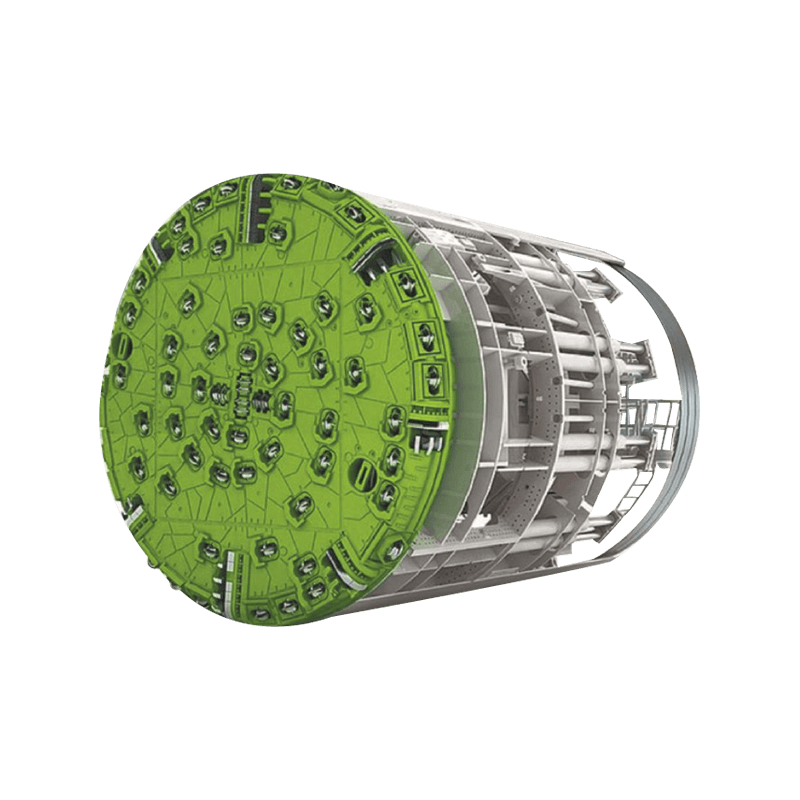

With the rapid development of computer technology, sensor technology and laser technology, modern pipe jacking machines are equipped with advanced positioning and navigation technology. These technologies can monitor the pipeline's advancement direction, depth, position and other data in real time, and adjust them through the automated system to ensure the accurate laying of the pipeline underground.

Specific performance:

Laser guidance system: Through the laser device, the pipe jacking machine can ensure the straightness and position accuracy of the pipeline, avoiding errors caused by deviation from the predetermined path during construction.

GPS positioning system: Through real-time GPS data, the position and advancement status of the pipeline can be accurately monitored to ensure the accurate docking of the pipeline underground.

Real-time data feedback: Through the sensors installed on the pipe jacking machine, construction personnel can obtain the working status of the machine in real time to ensure the accurate installation of the pipeline.

Application scenario: For example, in a complex urban underground environment, the pipe jacking machine needs to cross existing underground facilities (such as power lines, water pipes, gas pipes, etc.). The accurate positioning and navigation system can effectively avoid these facilities and reduce the risk of accidents.

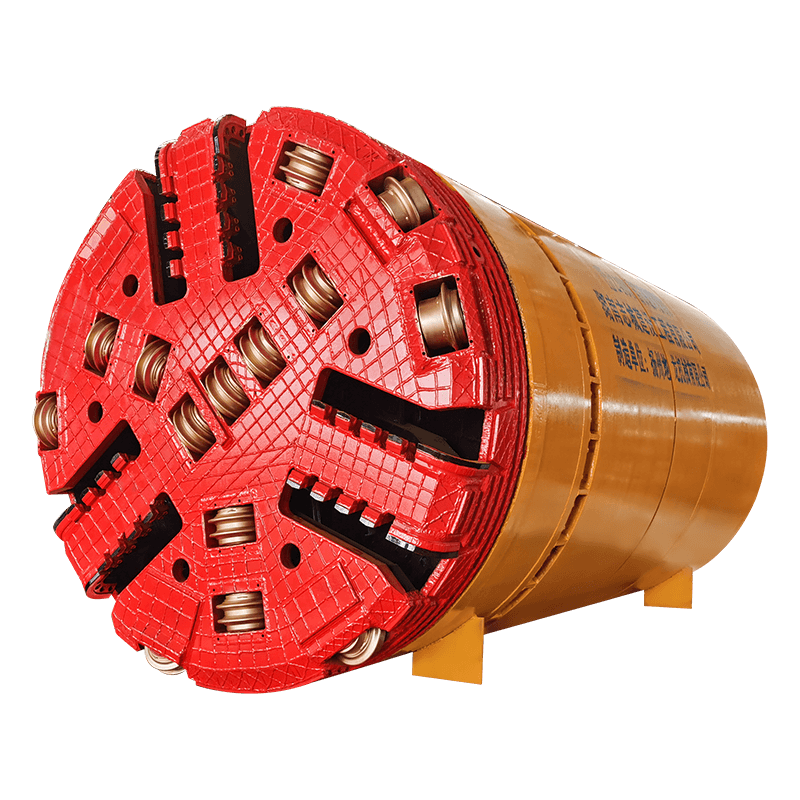

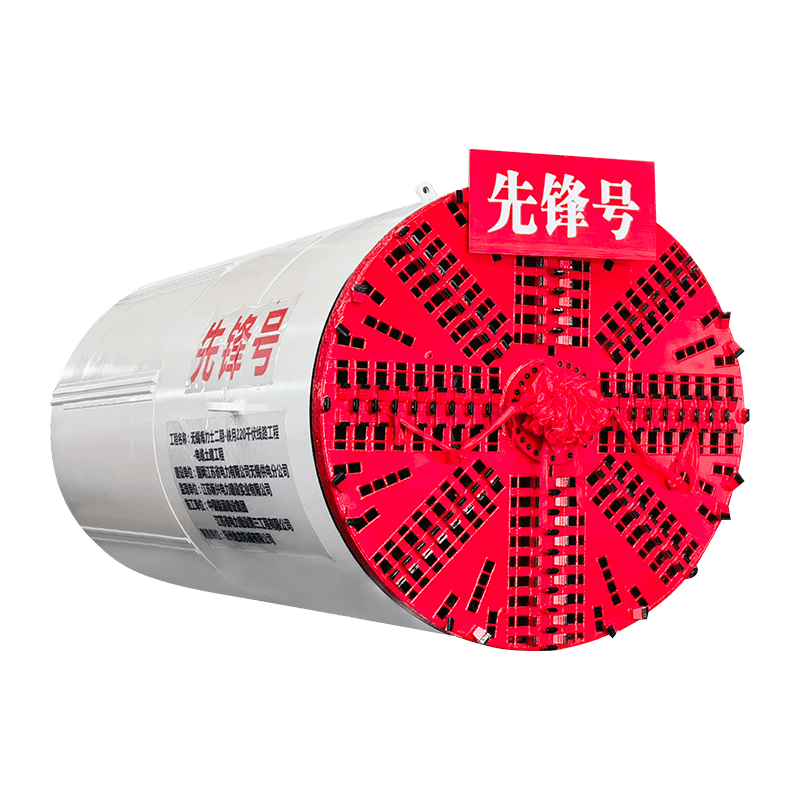

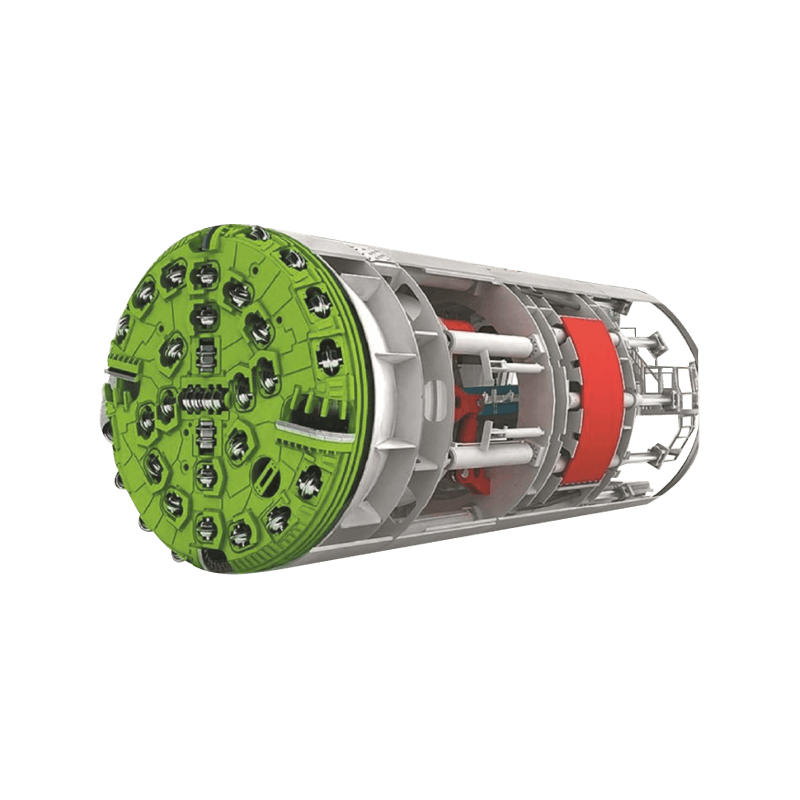

3. Adapt to complex geological conditions

Modern pipe jacking machines can adapt to various complex underground geological environments, such as loose sand, hard rock, slippery mud, etc., which enables them to continue to operate smoothly under changing geological conditions. According to different soil types and groundwater levels, the tool system and propulsion force of the pipe jacking machine will automatically adjust to ensure the smooth advancement of the pipeline.

Specific performance:

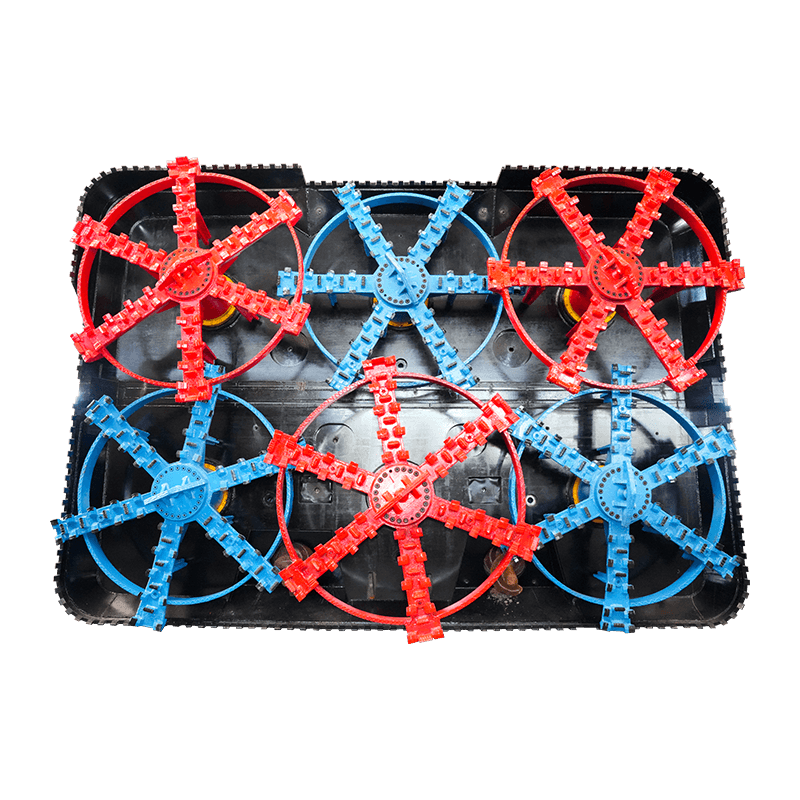

Tool system: Pipe jacking machines are usually equipped with different types of tools, which can be automatically replaced according to different geology to handle different materials such as soft soil, sand, hard rock, concrete, etc.

Pressure regulation system: In areas with high water levels or more groundwater, the pipe jacking machine can automatically adjust the propulsion pressure to prevent the pipeline from being affected by excessive water pressure.

Waterproof and mud-proof design: In places with high groundwater levels, the design of the pipe jacking machine takes into account waterproof measures to avoid groundwater infiltration or mud infiltration causing equipment damage.

Application scenarios: When crossing rivers, mountainous areas, and areas with high groundwater levels, traditional excavation methods may face greater construction difficulties or safety hazards, while pipe jacking machines can effectively cope with these complex geological conditions and ensure smooth construction.

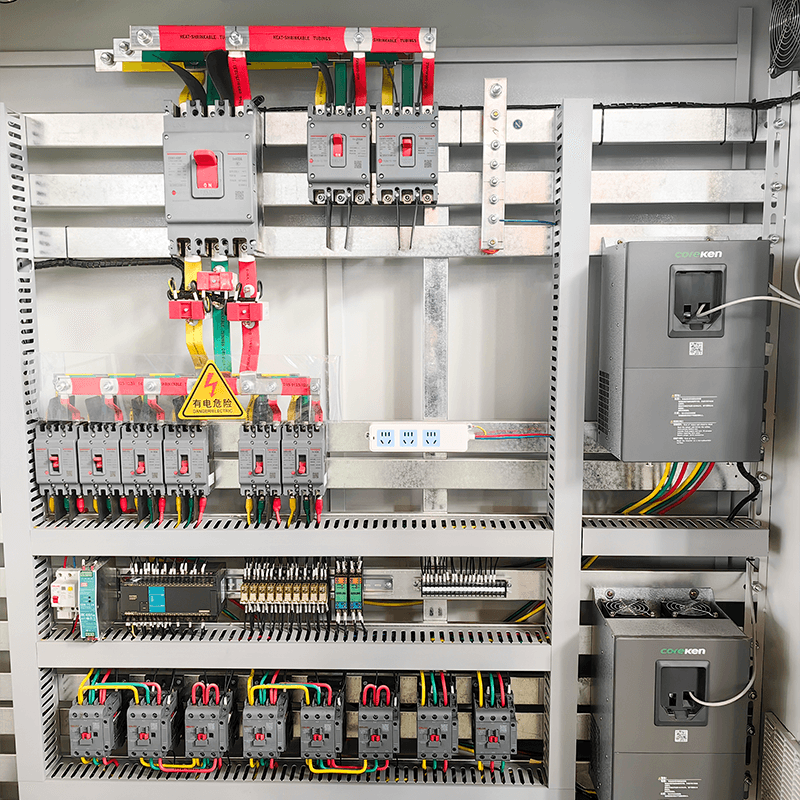

4. High automation and intelligence

Modern pipe jacking machines are increasingly tending towards high automation and intelligence. By integrating advanced computer control systems, modern pipe jacking machines can carry out efficient construction with less human intervention. This intelligent technology makes the construction process safer, reduces human errors, and improves construction accuracy and efficiency.

Specific performance:

Automated control system: The pipe jacking machine is equipped with an automated control system that can automatically adjust the propulsion speed, pressure and direction according to the construction environment to ensure work accuracy.

Remote monitoring and operation: Through the remote operation platform, the staff can monitor the working status of the pipe jacking machine in real time and adjust the machine remotely, which greatly improves the flexibility and safety of operation.

Fault diagnosis system: Through the intelligent monitoring and self-diagnosis system, the pipe jacking machine can automatically alarm and troubleshoot when a fault occurs, ensuring that the equipment can be discovered and solved as soon as possible when problems occur, avoiding major accidents.

Application scenario: In some high-risk environments, automation and intelligent systems can greatly reduce the risk of manual operation. For example, in bad weather, complex geology or densely populated urban underground operations, automated operations can better protect the safety of construction workers.

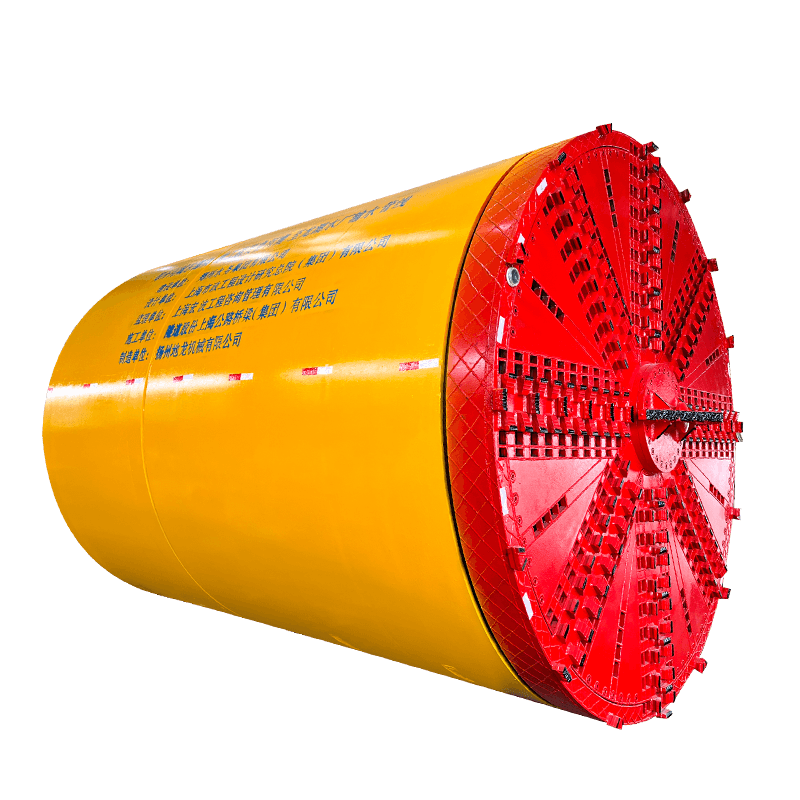

5. Compact structural design

The structural design of modern pipe jacking machines is more compact and relatively small, enabling them to operate more flexibly in urban underground environments with limited space. The compact design not only improves the maneuverability of the pipe jacking machine, but also better adapts to the complex pipeline layout of the urban underground pipeline network.

Specific performance:

Miniature design: Modern pipe jacking machines adopt a miniaturized design, which can smoothly advance the pipeline even in the narrow urban underground space, and has stronger adaptability.

Adjustable working width: Some pipe jacking machines can adjust the working width according to construction needs to adapt to the construction of pipelines with different diameters.

Application scenario: When laying pipelines in the central area of the city or old urban areas, the compact design of modern pipe jacking machines can avoid large-scale excavation and demolition, and reduce the impact on the urban environment and residents' lives.

6. Environmental protection and low noise operation

Modern pipe jacking machines emphasize environmental protection and low noise design, especially when constructing in urban environments, it is very important to reduce noise pollution and exhaust emissions. By optimizing the design and adopting advanced noise control technology, modern pipe jacking machines can reduce the impact on the surrounding environment during construction.

Specific performance:

Low noise design: By using noise suppression technology, the noise generated by the pipe jacking machine during operation is minimized, reducing interference with surrounding residents and the environment.

Reduced pollution emissions: Modern pipe jacking machines reduce exhaust emissions and other pollution sources during construction by optimizing the power system and using environmentally friendly materials.

Application scenarios: Low-noise and environmentally friendly pipe jacking machines are particularly suitable for construction sites in urban bustling areas or near residential areas, which can avoid disturbances to the surrounding environment and residents.

7. Modularity and scalability

Modern pipe jacking machines adopt a modular design and can be flexibly configured and expanded according to the needs of the construction project. For example, different cutters and propulsion systems can be selected according to different pipe sizes, propulsion requirements or geological conditions. This design makes the pipe jacking machine highly adaptable and scalable.

Specific performance:

Modular components: The various components of the machine can be replaced or upgraded according to needs, ensuring that the pipe jacking machine can adapt to different construction requirements.

Customizable configuration: The pipe jacking machine can be customized according to the specific needs of the project, and different functional configurations can be selected to improve the working efficiency of the machine.

Application scenarios: In multiple urban construction or large projects, the modular design of the pipe jacking machine allows different construction teams to flexibly select equipment configurations according to site conditions, thereby achieving efficient and economical construction.

English

English  русский

русский  عربى

عربى