When it comes to modern tunnel construction, few technologies have revolutionized the industry as profoundly as the Slurry Balance Tunneling Machine (SBTM). This engineering marvel ensures precision, safety, and efficiency in underground excavation projects, making it a standout choice for complex and demanding environments. Whether constructing metro systems beneath bustling cities or laying pipelines under challenging terrains, the SBTM offers capabilities that set it apart from traditional tunneling methods.

What Makes Slurry Balance Tunneling Machines Unique?

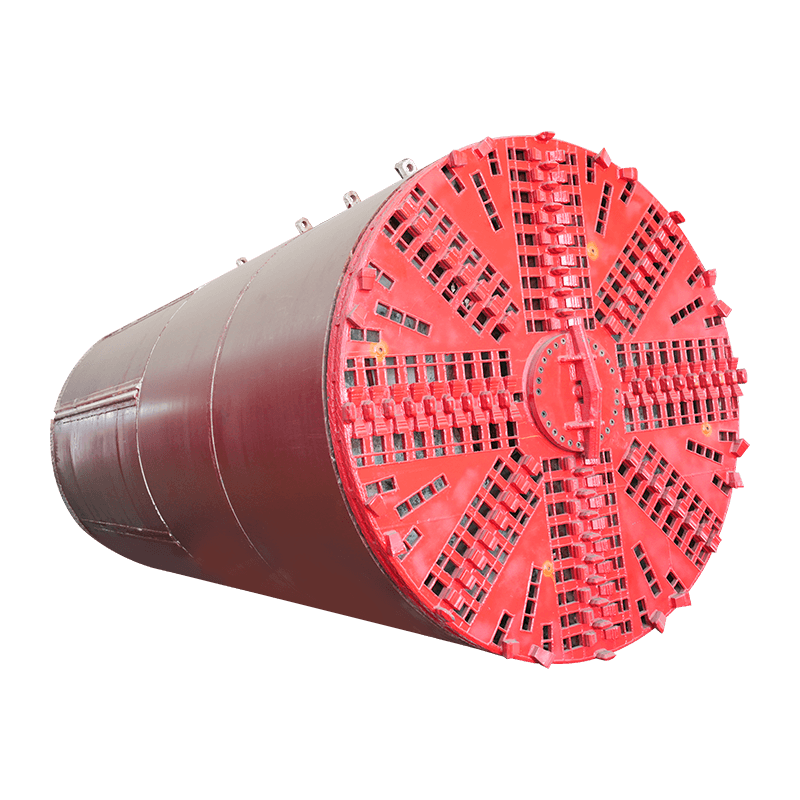

At its core, the slurry balance tunneling machine operates by maintaining a delicate equilibrium between the pressure inside the tunnel face and the surrounding ground. This is achieved through the use of a pressurized slurry mixture—typically composed of bentonite clay and water—that stabilizes the excavation area. The slurry not only prevents soil collapse but also carries excavated material out of the tunnel, ensuring continuous progress without compromising structural integrity.

This balance is critical when working in soft soils, mixed ground conditions, or areas with high groundwater levels. By controlling earth and water pressures, the machine minimizes the risk of surface subsidence, protecting nearby infrastructure such as roads, buildings, and utilities. For projects located in densely populated urban centers or ecologically sensitive zones, this feature alone makes the SBTM an invaluable asset.

Key Advantages of Choosing Slurry Balance Technology

Superior Ground Stability

One of the most significant advantages of using a slurry balance tunneling machine is its ability to maintain consistent ground stability throughout the excavation process. Unlike open-face tunnel boring machines, which rely on direct mechanical support, the slurry system provides uniform pressure across the entire tunnel face. This reduces the likelihood of unexpected ground movements, ensuring safer operations even in unstable geological formations.

Enhanced Environmental Protection

Modern tunneling projects often require strict adherence to environmental regulations. With its closed-loop slurry circulation system, the SBTM minimizes the release of sediments and pollutants into the surrounding environment. Additionally, the controlled removal of spoil material helps preserve local ecosystems, making it a more sustainable option compared to conventional excavation techniques.

Versatility Across Diverse Conditions

From sandy soils to clay-rich layers, the slurry balance tunneling machine adapts seamlessly to varying ground conditions. Its robust design allows it to tackle projects in coastal regions, riverbeds, and other water-saturated environments where traditional methods might falter. This versatility ensures reliable performance regardless of location, reducing delays and cost overruns.

Improved Safety Standards

Worker safety remains a top priority in any construction endeavor. The enclosed nature of the slurry balance system shields operators from potential hazards associated with collapsing tunnels or flooding. Furthermore, advanced monitoring systems integrated into the machine provide real-time data on pressure levels, allowing for proactive adjustments to mitigate risks.

Higher Productivity Rates

Efficiency is another hallmark of the SBTM. By automating key aspects of the excavation process—such as material transport and face stabilization—the machine significantly boosts productivity. Continuous operation reduces downtime, enabling faster completion of tunnel segments while maintaining quality standards.

Applications of Slurry Balance Tunneling Machines

The applications of these machines are vast and varied. In urban settings, they play a pivotal role in building subways, drainage systems, and utility tunnels without disrupting daily life aboveground. In industrial contexts, they facilitate the installation of oil and gas pipelines, sewer networks, and hydropower conduits, even in remote or environmentally fragile areas.

For example, consider a project involving the construction of a new subway line beneath a major city. Traditional methods may involve extensive surface disruption, noise pollution, and prolonged timelines. However, deploying a slurry balance tunneling machine can streamline the process, keeping the focus below ground while preserving the integrity of existing structures.

Similarly, imagine a scenario where a pipeline must traverse a riverbed or marshland. The SBTM's ability to manage hydrostatic pressures and prevent seepage ensures successful execution, even in these challenging scenarios.

English

English  русский

русский  عربى

عربى