In the ever-evolving world of construction, where precision meets power, auger boring machines have emerged as indispensable tools for trenchless technology. These machines, designed to drill horizontally through soil and other materials, have revolutionized how underground infrastructure is installed. From water mains and sewer lines to gas pipelines and electrical conduits, auger boring machines are reshaping the landscape of subsurface construction.

What Exactly Is an Auger Boring Machine?

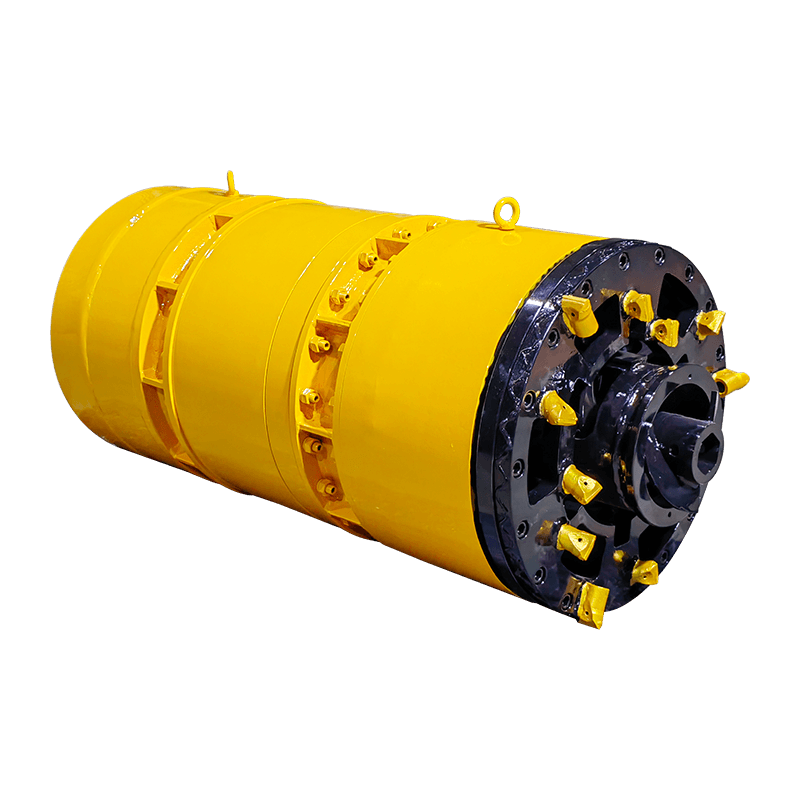

At its core, an auger boring machine operates by using a rotating helical screw blade—known as an auger—to excavate soil while simultaneously installing a pipe or casing. The process begins with a launch pit, where the machine is positioned to bore horizontally into the ground. As the auger turns, it carries the excavated material back to the entry point, allowing workers to remove it efficiently. This method minimizes surface disruption, making it ideal for urban environments, road crossings, and areas with sensitive ecosystems.

Auger boring machines come in various sizes and configurations, from small, portable units for light-duty projects to massive rigs capable of handling large-diameter bores over long distances. Their versatility makes them suitable for a wide range of applications, particularly when working with softer soils like clay, sand, or silt.

Why Choose Auger Boring?

One of the standout advantages of auger boring is its ability to maintain accuracy and control during installation. Unlike some other trenchless methods, such as horizontal directional drilling (HDD), auger boring provides a high degree of precision, ensuring that pipes are installed on the exact alignment and grade required. This level of accuracy is crucial for gravity-fed systems like storm drains and sanitary sewers, where even minor deviations can lead to costly repairs down the line.

Another key benefit is cost-effectiveness. Auger boring is often more affordable than alternative techniques, especially for shorter bores or projects involving rigid materials like steel or concrete casing. Additionally, because the process involves minimal surface disturbance, there’s less need for restoration work afterward, further reducing expenses.

Challenges and Innovations

Despite their many benefits, auger boring machines aren’t without challenges. Hard rock formations, for example, can pose significant obstacles, requiring additional equipment or modifications to the standard setup. To address these limitations, manufacturers are continually innovating, introducing features like enhanced torque capabilities, modular designs, and advanced guidance systems.

Recent advancements in automation and remote operation are also transforming the industry. Operators can now monitor and adjust parameters in real time, improving safety and efficiency on the job site. These technological upgrades not only make auger boring safer but also expand its potential applications, bringing it closer to becoming a universal solution for underground utility installations.

English

English  русский

русский  عربى

عربى